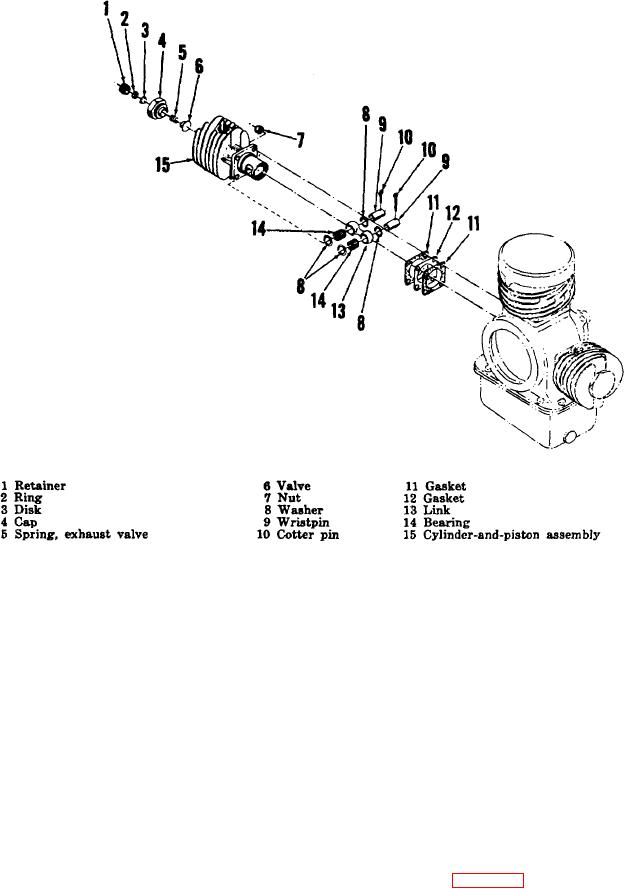

Figure 3-6. Third stage section, exploded view.

d. Assembly.

(4) Pull cotter pins (10) releasing wrist-

pins (9). Remove wrist-pins, washers

(8), bearings (14), and link (13)

Note. To measure and adjust piston-

releasing piston from rod.

head-to-valve-seat clearance, install

first or second stage cylinder-and-

Note. The cylinder and piston are

piston assembly to guide the cylinder

matched parts. Do not separate the

being measured and adjusted.

cylinder and piston or mix with

similar

components

of

other

(1) Place 25 needle rollers (14) around

compressors. Scribe small marks

edge of wrist-pin hole in one end of

third stage connecting link (13).

inside skirts to identify side of piston

Place link washer (8) at ends of needle

that was toward fan end of

rollers. Position connecting link inside

piston of cylinder-and-piston assembly

(15) and press in wrist-pin (9). Secure

(5) Remove gaskets (11 and 12). Record

with cotter pin (10). Use petrolatum

thickness of gasket combination and

discard.

(2) Assemble 25 needle rollers (14) and

two link washers (8) in wrist-pin hole of

Note. By measuring the thickness of

connecting link (13). Pass free end of

removed gaskets and adding 0.005

third stage connecting link (13)

inch for each new proper gasket to

allow for crush at installation, new

gaskets required to obtain proper

clearance can be selected with ease

during reassembly.

24