TM 3-1040-263-34

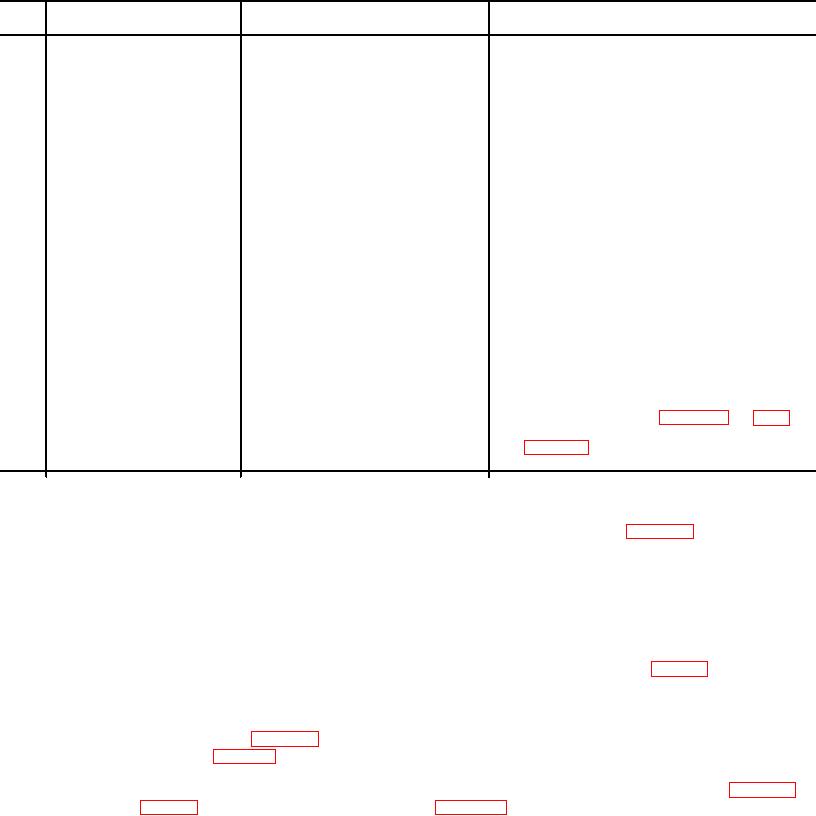

Table 4-4. Troubleshooting-Continued

Item

No.

Malfunction

Probable cause

Corrective action

a. Insufficient speed --------------

9

Low airflow or long fill time

Increase engine speed (TM 5-205-256-14).

b. High blowby --------------------

Refer to item 6 above

c. Insufficient inlet air compressor

Clean 1st-stage strainer and filter assembly

unit.

(TM 3-1040-263-12).

NOTE

When determining leaks, the

compressor should be

operating under normal

conditions.

d. Leaking or popping of relief valve _

Refer to item 2 above

e. Leaky fittings, heat exchanger con-

Replace leaky gaskets, packings or

nections, gaskets, packings, or

bushings.

any external leakage.

10

Inability to fill to rated

a. Low airflow or long fill time ------

Refer to item 9 above

pressure.

11

Insufficient speed and over-

a. Lack of lubrication --------------

Check oil level (TM 3-1040-263-12)

heating of compressor unit. b. Insufficient cooling air -----------

Operate compressor unit under prescribed

conditions with sufficient coolin g air.

a. Compressor failure or engine

Remove engine from compressor and

12

Inability of compressor unit to

turn over or reach speed

failure.

check each for freedom of movement.

Replace defective unit (para 4-32 or

b. Broken or loose crankshaft

Tighten or replace crankshaft adapter

adapter.

Section X. GASOLINE ENGINE GROUP

f.

Remove nut (1, fig. 4-18), lockwasher (2),

4-45. General

screw (3), and clamp (4).

General support maintenance personnel are authorized

g. Disconnect nuts of fuel line (5) from the

to replace the gasoline engine, crankshaft adapter,

filter (7) and elbow (16).

engine adapter, pulley, left and right-hand brackets,

h. Remove fuel line (5).

exhaust pipe, and attaching hardware. General support

i.

Remove cap screws (8) and lockwashers

maintenance personnel are also responsible for the

(9).

manufacture of the fuel line and tank clamps.

j. Remove gasoline engine (34) with assembled

4-46. Description

parts from the bottom frame (38, fig. 3-2).

TM 5-2805-256-14 describes the gasoline engine.

4-48. Disassembly

4-47. Removal

a. Remove canvas group (TM 3-1040-263-

12).

NOTE

b. Remove protecting cage (para 3-7).

c. Remove plug (15, fig. 3-2), and drain fuel

Except where stated, retain all removed parts for

tank (31).

installation on replacement engine.

d.

Disconnect aftercooler end nut from water

a. Remove crankshaft adapter (15, fig. 4-18)

separator elbow (19, fig. 3-1).

(para 4-52a(3) and (4).

e. Using the crankcase removal instructions

B

Remove the elbow (16) from the fuel filter

(para 432a), remove compressor from engine.

assembly (17).

c. Remove the fuel filter assembly (17) from

4-31