TM 3-4310-100-20 & P

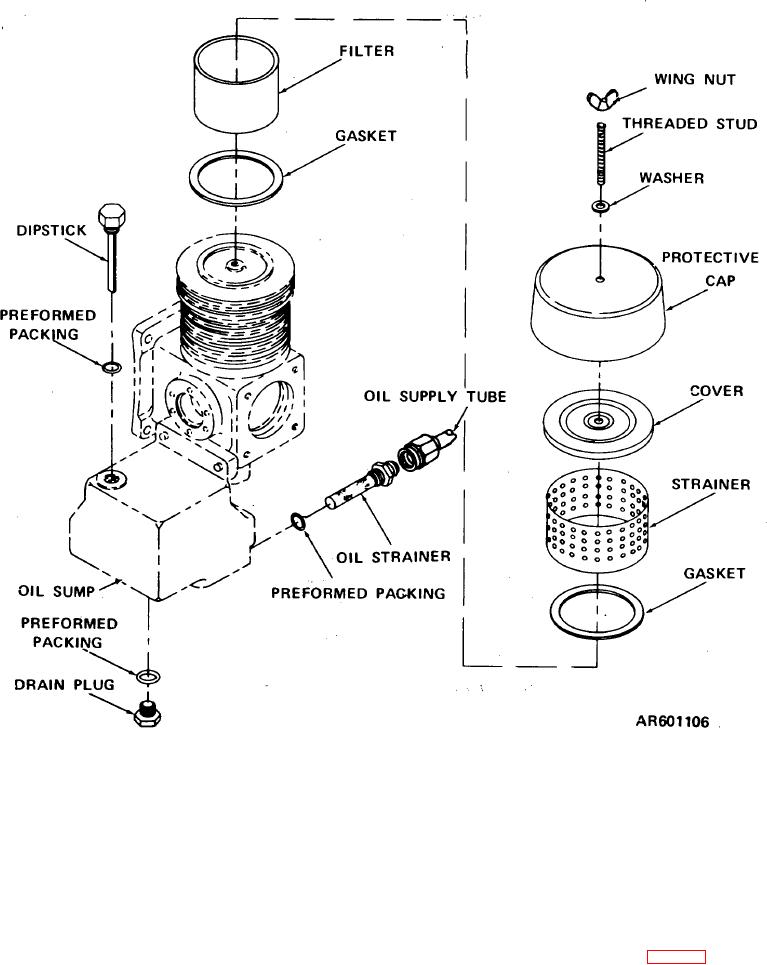

Figure 2-4. First stage strainer and filter assembly (AN-M4D model only)

b.

Adding Oil

Excessive high or low ambient

(1) Remove the oil breather cap or dipstick

temperatures (below 0 F or above 110

and wipe with a clean dry cloth.

F), prolonged periods of operation

(2) Add lubricating oil (NSN 9150-00-

(two hours or more) or operating in

7534667) to the air compressor as required to raise the

sand or dust will necessitate more

level of the oil within the oil level sight circle or on the

frequent change of the lubricant.

dipstick full mark.

(2) The 50-hour operation interval 3 based on

(3) Replace the oil breather cap or dipstick.

good operating conditions.

(4) Wipe any spilled oil from the compressor

(3) Drain the oil reservoir while the

unit.

compressor is turned off and still hot.

c. Changing Oil

(4) Remove the drain plug (fig. 2-2) and drain

(1) Change the oil in the compressor units

the oil from the reservoir.

after every 50 hours of operation.

CAUTION

2-5