TM 5-4310-227-15

sembly (18) with the bolt (28), two

lockwashers (23) and nut (40).

(8) Secure the magneto to the bottom side

of the cylinder and cranckcase assem-

bly with the capscrew (22) and lock-

washer (23).

(9) Turn the engine crankshaft over slow-

ly by hand. If the magneto is proper-

ly timed, the impulse coupling will

snap when the flywheel air vane tim-

i n g mark (X) (2, fig. 3-12) ap-

p e a r s in the top center inspection

hole (4, fig. 3-11).

(10) Install the magneto drive gear inspec-

tion plug (14 fig. 3-2) in the crank-

case gear housing.

(11) Position the high-tension cable outlet

in the ignition shield (13).

(12) Connect the ignition cable to the mag-

neto (para 3-45).

(13) The proper spark advance is 20 per-

cent. For checking timing with a neon

light, the running spark advance is

i n d i c a t e d through the timing hole

(3, fig. 3-11) located 20 before top

center on the air shroud rim (5). The

1

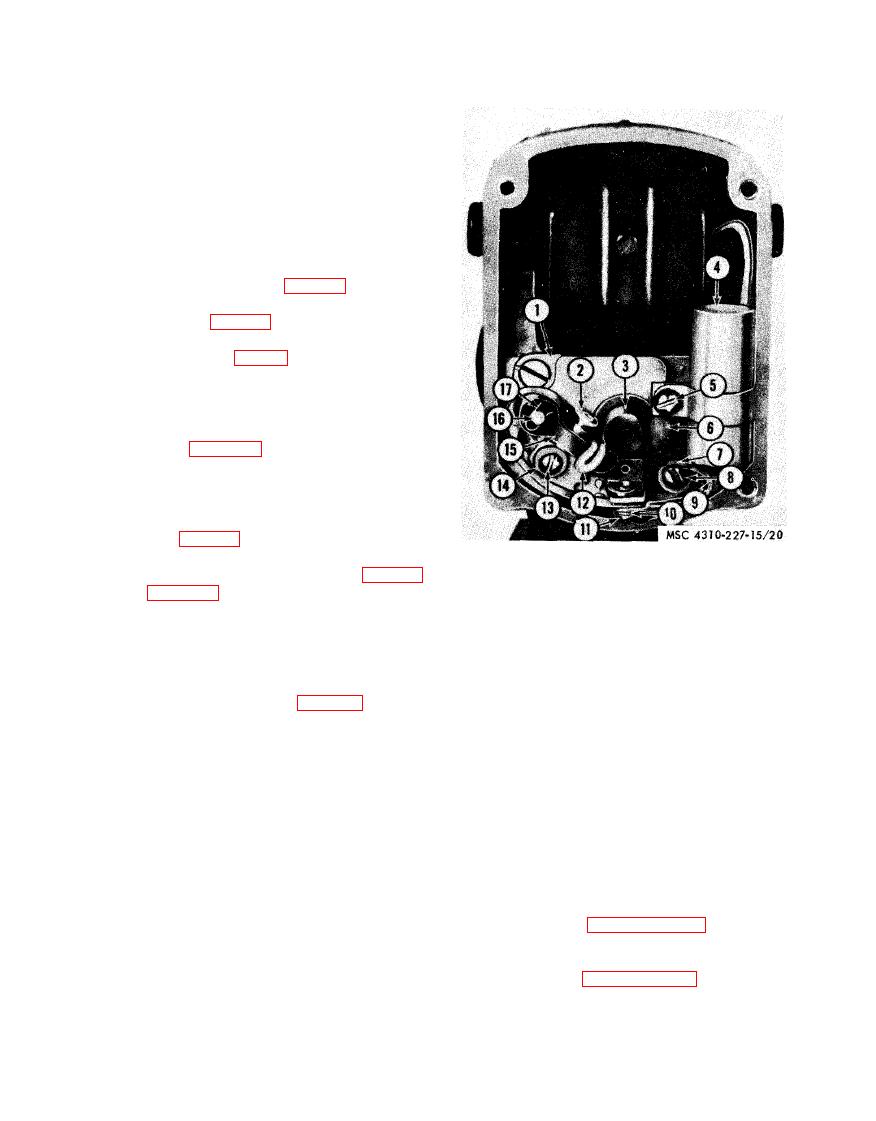

Bearing support plate assembly

air vane timing mark (X) (2, fig. 3-

2

Contact set support plate

Magneto rotor

3

paint for this operation.

4

Capacitor

d. Contact Set Adjustment.

5

Screw, mach. 8-32 X 1/4 in.

6

Camwick and holder assembly

(1) Remove the magneto ignition shield

7

Washer, flat, No. 8

(see (a) above).

8

Screw, mach, 8-32 X 3/8 in.

(2) Rotate the engine by hand until the

9

Lead

magnatic rotor (3, fig. 3-13) opens

10

Washer, lock, No. 6 (2 rqr)

the contact points to full separation.

11

Screw, math. 6-32 X 3/8 in.

12

Breaker arm flat wick

(3) Measure the gap setting of the con-

13

Screw, math. 6-32 X 3/8 in.

tact set by inserting a feeler gage be-

14

Washer, flat, No. 6

tween the breaker points. The proper

15

Breaker arm and spring

gap is 0.015 inch.

16

Fulcrum pin

(4) Loosen the contact support locking

Retaining ring

17

screws (8 and 13) just enough to al-

low movement of the contact set sup-

removal points.

port plate (2). Adjust the gap until

a light drag is felt as the feeler gage

(1) Remove the magneto ignition shield

is withdrawn.

(see a above).

(5) Tighten the locking screws (8 and

(2) Refer to paragraph 4-19 a (3), (4),

13) and recheck the gap setting.

and (5), for the removal of the con-

(6) Install the magneto ignition shield

tact set.

(see c above).

(3) Refer to paragraph 4-19 c (16), (17),

and (18), for the installation of the

e. Contact Set Replacement (Models BMW-

contact set.

452-ENG and BMW-452-ENG-1).

3-37