TM 5-4310-227-15

ENGINE COOLING AND EXHAUST SYSTEMS

Section VIII.

secure the backet (27) to the air

3-53. General

shroud (12).

The engine is forced-air-cooled from a blow-

er integrated with the flywheel. An air shroud

incloses the top and three sides of the engine

of the air shroud (22) to the front

cylinder with an intake opening at the blower.

of the cylinder and crankcase as-

Air from the blower is forced around and over

sembly (17).

the top of the engine to dissipate the heat. The

and fittings, provides a means of releasing the

cure the air shroud (36) to the rear

exhaust gases to the atmosphere. Refer to TM

and sides of the cylinder and crank-

5-2805-203-14 for data applicable to Model

case assembly (19 ) and remove the

OEG-458-ENG-3.

air shroud.

(h) Remove the four sheet spring nuts

(1, fig. 3-12) from the f ront of the

air shroud (4).

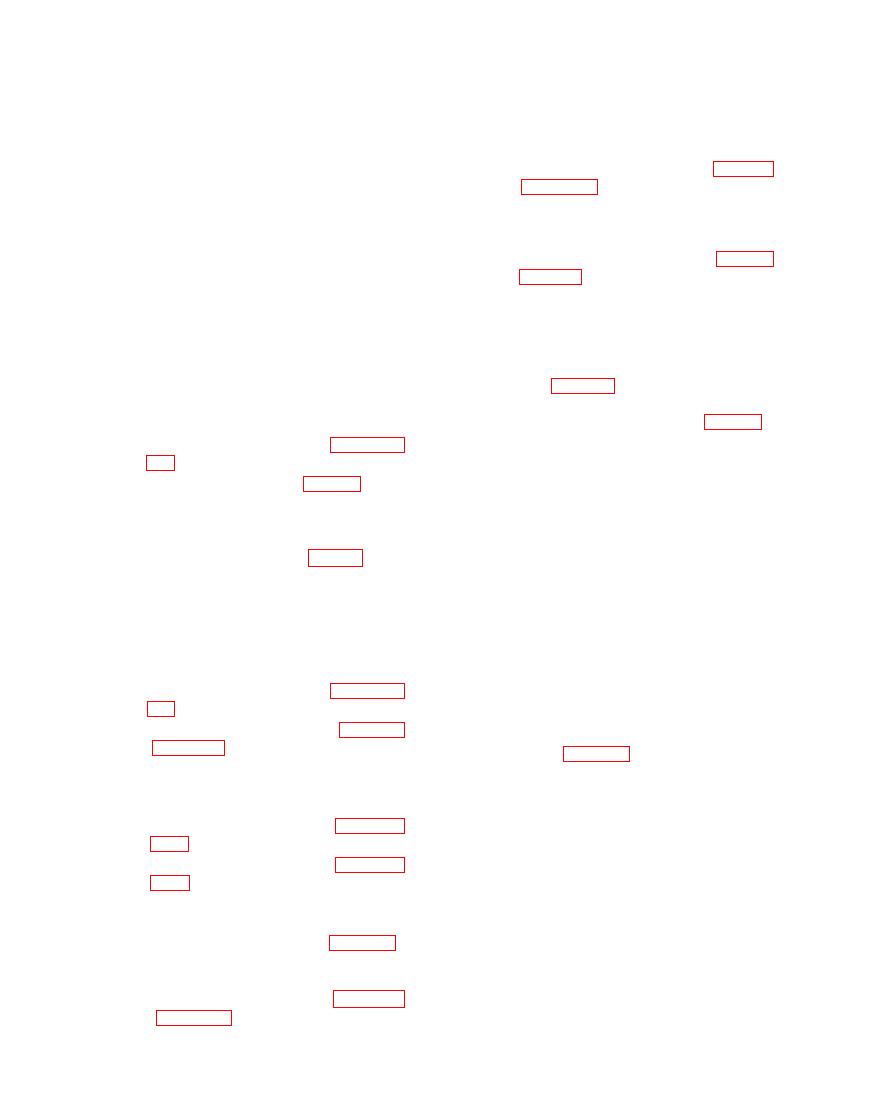

a. Removal.

(1) Air shroud cover.

l o c k w a s h e r , and nut that secure

the air cleaner bracket clip (20) to

the air shroud (22). Remove the

bracket clip.

lockwasher (5) that secure the air

b. Cleaning, Inspection, and Repair.

shroud cover (2) to the cylinder

(1) Clean the air shroud, cover, rim and

head stud (4).

screen with an approved cleaning sol-

vent and dry thoroughly.

secures the air shroud cover (7) and

(2) Inspect all applicable parts for dents,

shroud (22 ) to the side of the cylin-

cracks, breaks, and other damage.

der head (6) and remove the cover

(3) Inspect all threaded parts for dam-

and stud spacer from the engine

aged threads.

cylinder head.

(4) Repair or replace all defective parts

(2) Rim and screen.

as necessary.

c. Installation.

(1) Air shroud.

(a) Secure the air cleaner bracket dip

(21, fig. 3-18) to the air shroud

screen (6) to the air shroud (1).

( 2 2 ) with the screw (19),lock-

Remove the rim and screen.

washer (31), and nut (30).

(3) Air shroud.

(b) Position the four sheet spring nuts

(23) on the air shroud.

(c) Position the air shroud on the cyl-

inder and crankcase assembly (17)

and install the four screws (32)

(c) Remove the air shroud cover (see

and lockwashers (31) that secure

(1) above).

the air shroud to the rear and sides

of the cylinder and crankcase as-

sembly.

that secure the starter guard to the

air shroud.

(d) Install the two capscrews (25) and

lockwashrs (24) that secure the in-

side rear of the air shroud to the