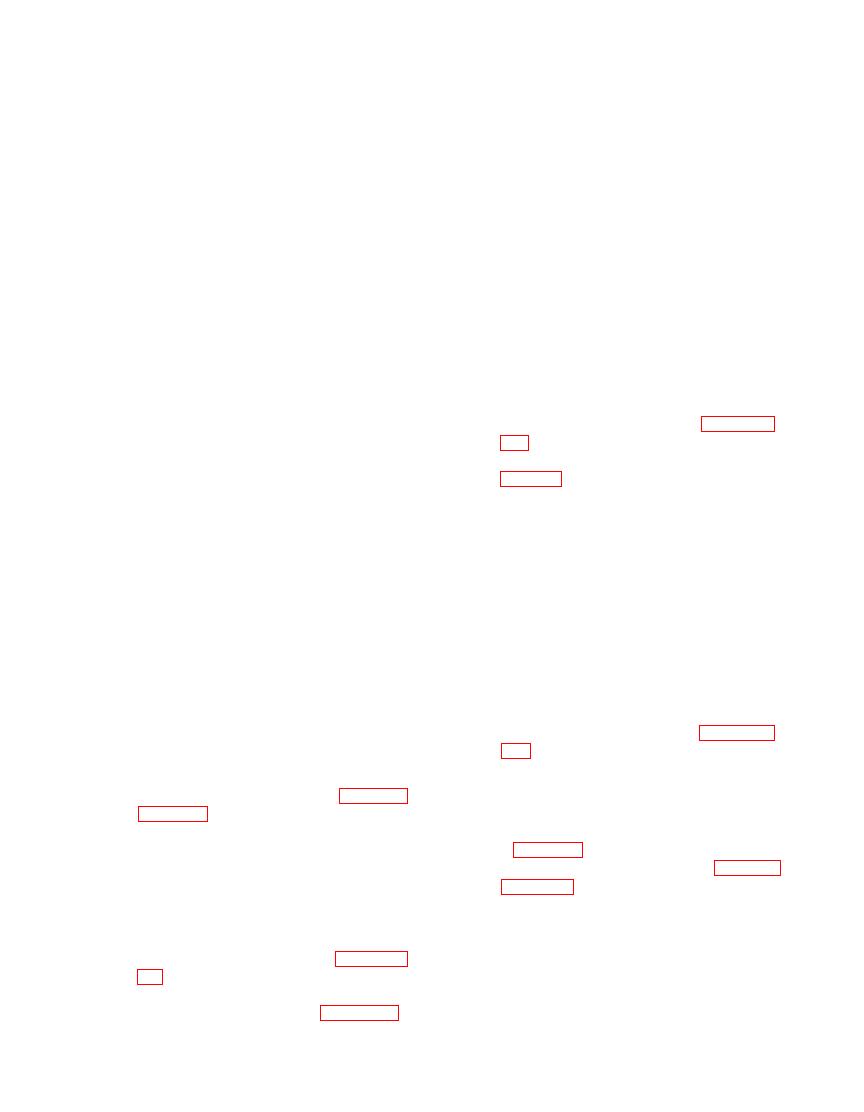

TM 5-4310-227-15

(2) Watch the pressure gage to see at

(3) Remove the unloader valve body (11)

what point the unloader valve opens.

from the lower body (9) by unscrew-

The unloader valve is adjusted cor-

ing it.

(4) Push the assembled piston and piston

rectly if it opens when the air pressure

rod (3) down through the unloader

reaches 175 psi.

(3) If the unloader valve opens before

valve body.

(5) R e m o v e the piston (4) and piston

the air pressure reaches 175 psi, turn

the nut (35) clockwise until the un-

packing (5) from the piston rod (3).

(6) Remove the body seat (6) and valve

loader valve is operating correctly.

(4) If the unloader valve opens after the

(8) from the lower body (9).

(7) Remove the gasket (7) from the body

air pressure has gone over 175 psi,

seat.

turn the nut counterclockwise until

the unloader valve is operating cor-

Note. Remove the gasket only if it

needs to be replaced.

rectly.

c. Cleaning, Inspection, and Repair.

(1) Clean all parts with an approved

cleaning solvent and dry throughly.

a. Removal.

(2) Inspect all parts for cracks, breaks,

(1) Remove the unloader valve (para 3-

w e a r , or other damage. Replace a

damaged part.

(2) Remove the aftercooler manifold (30,

d. Reassembly.

(1) Install the gasket (7) on the body

(3) Remove the pipe plug from the after-

seat (6).

cooler manifold.

(2) Install the body seat (6) and valve

b. Cleaning and Inspection.

(8) in the lower body (9).

(1) Clean all parts with an approved

(3) Install the piston (4) and piston pack-

cleaning solvent and dry thoroughly.

ing (5) on the piston rod (3).

(2) Inspect all parts for cracks, breaks,

(4) Push the assembled piston and piston

worn threads, rust, or other damage.

r o d (3) up through the unloader

Replace a damaged part.

valve body (11).

c. Installation.

(5) Install the unloader valve body (11)

(1) Install the pipe plug in the aftercool-

on the lower body (9).

er manifold.

(6) I n s t a l l the spring (12) and spring

(2) Install the aftecooler manifold (30)

button (13) on the piston rod (3)

in the check valve (28).

and secure with the nut (1).

(3) Install the unloader valve (para 3-

(7) Install the pipe plug (10) in the low-

er body (9).

e. Installation.

(1) Install. the pipe nipple (32, fig. 3-

a. Removal.

(1) Remove the

manifold

aftercooler

(2) Install the unloader valve (34) and

pipe nipple (32) on the aftercooler

(2) Remove the check valve (28, fig. 3-

manifold (30).

(3) Install the unloader valve (34) in the

pipe tee (26) and remove the pipe

bushing (25).

nipple from the check valve. Remove

(4) Connect the sensing tube (31) and

the pipe tee (26) and nipple from the

tighten the compression nuts (29).

air receiver tank.

(5) Install the aftercooler tube (para 3-

b. Cleaning and Inspection.

(1) Clean all parts with an approved

f. Adjustment.

cleaning solvent and dry thoroughly.

(1) Start the air compressor (para 2-26).

3-72