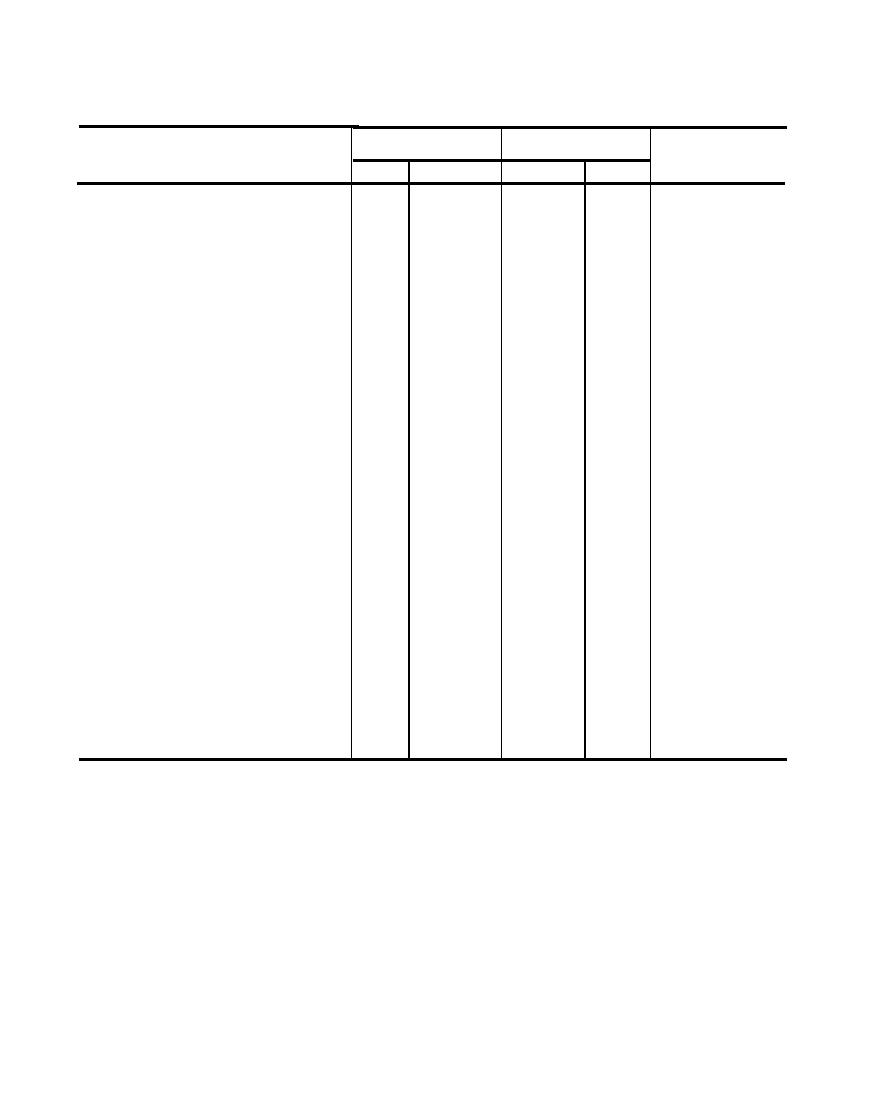

TM 5-4310-227-15

Manufacturer's dimensions

Desried clearance

Maximum allowable

and tolerances in inches

wear and

clearance

Min.

Max.

Max

Min.

Cylinders:

Bore, low-pressure_________________

4.625

0.006

4.626

0.003

0.002

___

___

Bore, high-pressure ______________

2.500

0.006

2.5005

___

___

___

Taper ____________________________

0.001

0.001

___

___

Out-of-round _____________________

0.002

0.001

0.001

Crankshaft:

_

_

_

_

_

_

_

_

_

Journal size, main bearing ________ 1.376

1.377

_

_

_

_

_

_

_

_

_

Journal size, connecting rod ________ 1.375

1.376

Journal out-of-round _____________ _ _ _

_

_

_

_

_

_

_

_

_

0.0005

_

_

_

Journal taper ______________________ _ _ _

_

_

_

_

_

_

0.0002

Piston, piston pins, and piston rings:

___

Piston size, low-pressure _________

___

4.6195

4.6200

0.0015

___

___

piston size, high-pressure ________

2.4970

2.4975

0.0015

___

___

Piston pin diameter, low-pressure _____

0.001

0.93750

0.93775

___

___

Piston pin diameter, high-pressure ___

0.93775

0.001

0.93750

___

___

___

2.118

Piston pin length, high-pressure ____

2.123

___

___

___

4.250

Piston pin length, low-pressure _____

4.250

___

___

___

Piston pin clearance in piston ____

0.0009

0.0002

Piston to cylinder clearance, low-

___

___

___

0.0055

0.00050

pressure _______________________

piston to cylinder clearance, high-

___

___

___

0.0030

0.0025

pressure _______________________

Piston ring side clearance, low-pres-

___

___

___

0.0025

0.0010

sure ___________________________

Piston ring aide clearance, high-pres-

___

___

___

0.0045

0.0010

sure ____________________________

___

___

___

0.013

0.023

Piston ring gap, low-pressure _________

___

___

___

0.007

0.017

Piston ring gap, high-pressure ________

Connecting rods and bearings:

___

Bearing running clearance ___________ _ _ _

___

0.0016

0.0003

___

Bearing side clearance ______________ _ _ _

___

0.0012

0.0040

___

___

___

Bearing internal diameter ___________ 1.355

1.357

Section Ill. SPECIAL TOOLS AND EQUIPMENT

tenance repair parts are listed and illustrated

in TM 5-4310-227-25P.

No special tools or equipment are required

to perform field and depot maintenance on the

air compressors.

and Equipment

No specially designed tools or equipment are

Depot Maintenance Repair Parts

required to perform direct and general support

and depot maintenance on the air compressors.

Direct and general support and depot main-