COMPRESSOR REPAIR INSTRUCTIONS

for proper fit. Aline or replace the connect-

92. General

ing rods, if necessary.

The compressor assembly is a two-stage, three-

(4)

Not used.

cylinder, air-cooled unit. There are two low-pressure

(5)

Measure the ring groove in the pistons for

pistons and one high-pressure piston operating off

wear. Replace the pistons if necessary.

the crankshaft. The major repair instructions are

(6)

Inspect the crankshaft for cracks, scores,

those covering the pistons, connecting rods, and

and distortion, Measure the crankshaft

crankshaft.

bearing journals for wear. If the connect-

ing rod journals measure 0.005 inch out-of-

Crankshaft

round, replace the crankshaft.

a. Removal and Disassembly.

Inspect the roller bearings for rough, pitted,

(7)

or scored bearings. Replace a defective

(1)

Remove the tube assemblies (para 69).

bearing.

Remove the belt guard (para 66).

(2)

(3)

Remove the V-belts (para 67).

c. Reassembly and Instalation.

Remove the compressor (para 65).

(4)

(1) Reassemble the pistons and connecting rods

Remove the hand hole plate (11, fig, 18).

(5)

in the reverse order of that given in figure

(6)

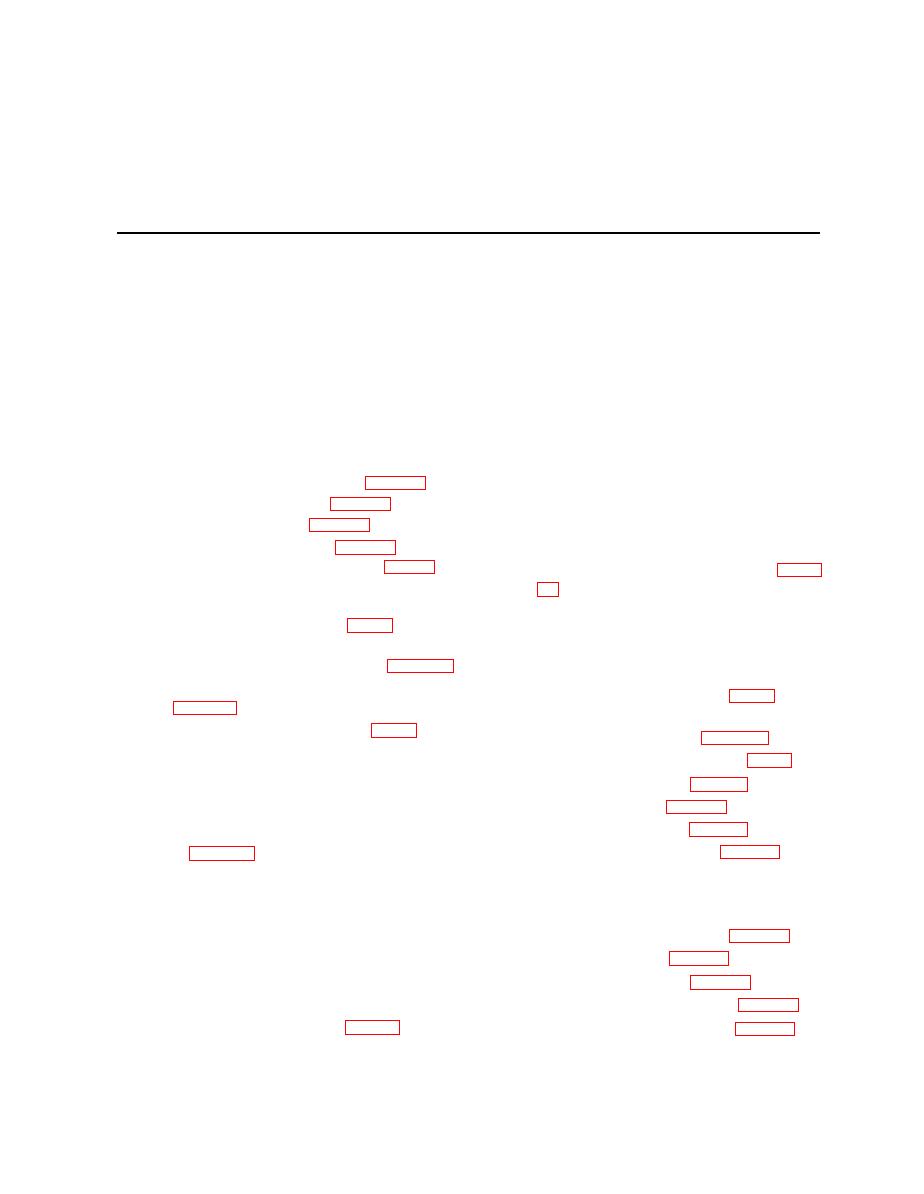

Revolve the crankshaft until the connect-

ing rod nuts are accessible through the

(2) Lubricate each piston, and connecting rod

bottom of the crankcase (fig. 24).

assembly with a light coat of oil.

(7) Remove the units, lockwashers, oil scoops,

(3) Install the piston and connecting rod as-

and bearing caps as illustrated in figure 24.

semblies in the cylinders and install the

(8) Remove the crankshaft as illustrated in

cylinders on the crankcase (fig. 18).

(4) Install the crankshaft and connecting rod

(9) Remove each cylinder block (fig. 18) with

bearings as illustrated in figure 24.

the piston and connecting rod in it from the

(5) Install the hand hole plate (11, fig. 18)

(6) Install the compressor (para 65).

(10) Pull the assembled piston and connecting

(7) Install the V-belts (para 67).

rod from each block and disassemble the

(8) Install the belt guard (para 66).

unit in numerical sequence as illustrated

(9) Install the tube assemblies (para 69).

in figure 25.

b. Cleaning, Inspection, and Repair.

94. Hand Truck Assembly

(1) Clean all parts in an approved cleaning

a. Removal and Disassembly.

solvent and dry thoroughly.

(1) Remove the air compressor (para 65).

(2) Inspect the cylinder blocks for cracks and

(2) Remove the engine (para 57).

breaks. Inspect the cylinder bores for wear,

(3) Remove the fuel tank (para 60).

scoring, pitting, or other damage.

(4) Remove the air receiver tank (para 74).

(3) Measure the clearance of the piston pin to

the piston pin backing (table 1). Check

(5) Remove the wheel assemblies (para 80).