TM 5-4310-277-14

crimped. Check that the glass bowl on the fuel filter

tank is being filled. Always provide a metal-

is secure and not cracked or broken.

to-metal contact between the container and

tank to prevent a spark from being

g. Correct all deficiencies or report them to the

proper authority.

generated as gasoline flows over the

metallic serfaces.

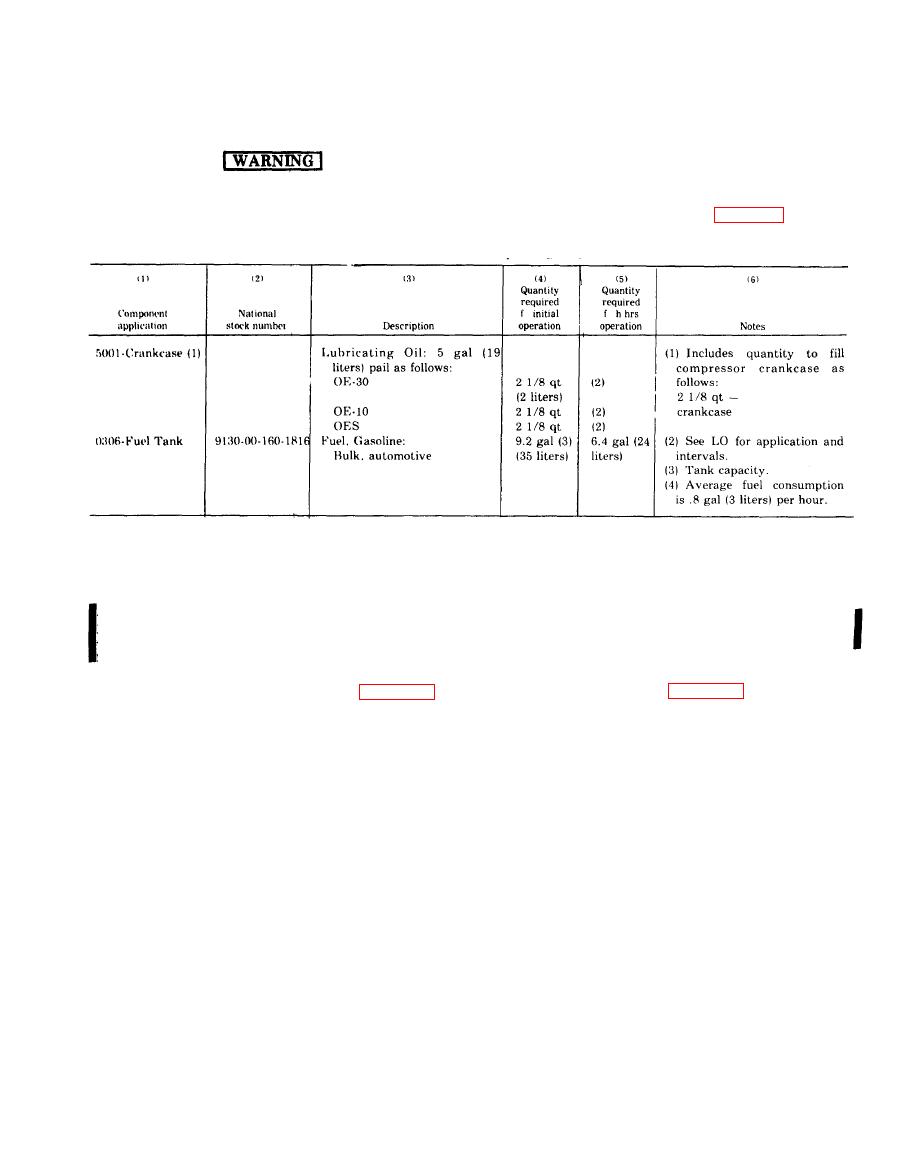

h. The maintenance and operating supplies

Do not fill the fuel tank while the engine is

running. Be sure there are no open flames

required for the initial eight hours of operation for

that may ignite the fuel vapors while the

the compressor are contained in table 4-1.

4-2. Installation

a. Installation of Separately Packed Com-

b. Installation or Setting Up Instructions.

ponents.

(1) General. Model BGR-5M-1 is primarily

designed for mobile field use when trailer mounted

and requires no special base. The Models HGR5-8M-

hose assembly, inflator gage (and globe valve with

1, and HGR5-8M-6 set directly on four feet welded

Models HGR5-8M-1 and HGR5-8M-6), packed sepa-

to the bottom of the air receiver and may be per-

rately.

manently installed if desired. If a permanent base is

(2) Install the air hose assembly, inflator

to be constructed, refer to figure 4-4.

gage, and globe valve as illustrated in figure 4-5.

Change 1