TM 5-4310-349-14

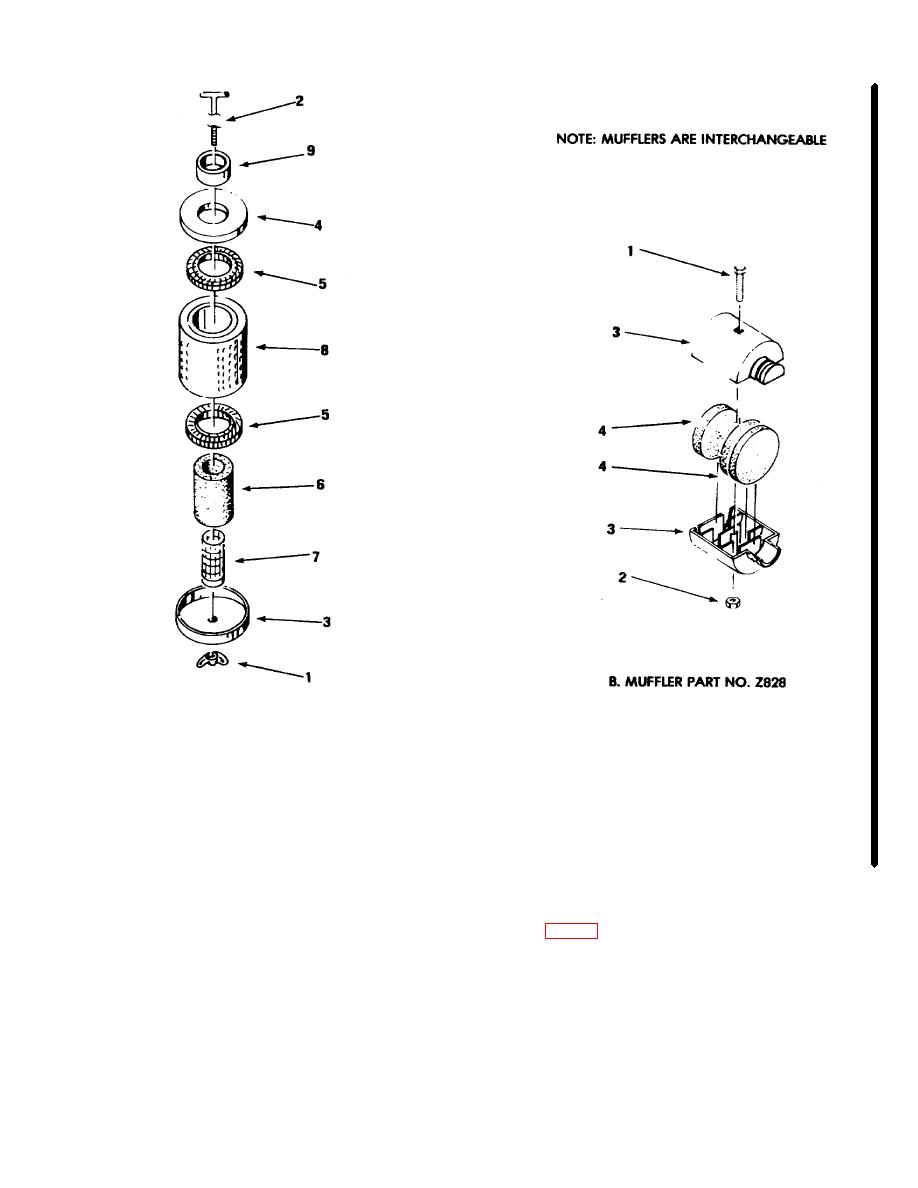

1.

SCREW MACHINE

A.

MUFFLER PART NO. Z66A

2.

PLAIN

3.

INTAKE, AIR

1.

T-STUD

5.

SEPARATOR

4.

FILTER ELEMENT

2.

NUT, WING

6.

ELEMENT

3.

COVER, LOWER

7.

SCREEN

4.

COVER, UPPER

8.

PLATE

9.

FERRULE

ME 4310-133-3512-14/3-3

Figure 3-3. Air intake mufflers, exploded view

moisture (condensate) into the receiver.

Frequent

c.

Draining Condensate from Air Receiver.

inspection and service is necessary.

(1) TURN ON-OFF switch to OFF.

b. Inspection and Cleaning.

(2) Open draincock at bottom of the air

(1) Inspect the receiver for excessive

receiver (fig. 1-1) under the service line.

accumulation of dust, and leaking or spilled compressor

(3) When air has escaped, leave draincock

oil.

open for a few minutes for more of the condensate to

(2) Check air lines and the service line for

escape.

leaking joints or damaged lines. Tighten loose fittings,

(4) Close draincock.

replace a damaged line.

(5) Be sure that all cloths, tools, etc., have

(3) Use compressed air to blow dust off the

been removed from the air receiver, then move ON-

receiver and all components mounted thereon. Wipe off

OFF switch to ON.

all oil spots, then dry, to avoid further accumulations.

Change 2 (3-8 blank)/3-7