TM 5-4310-354-14

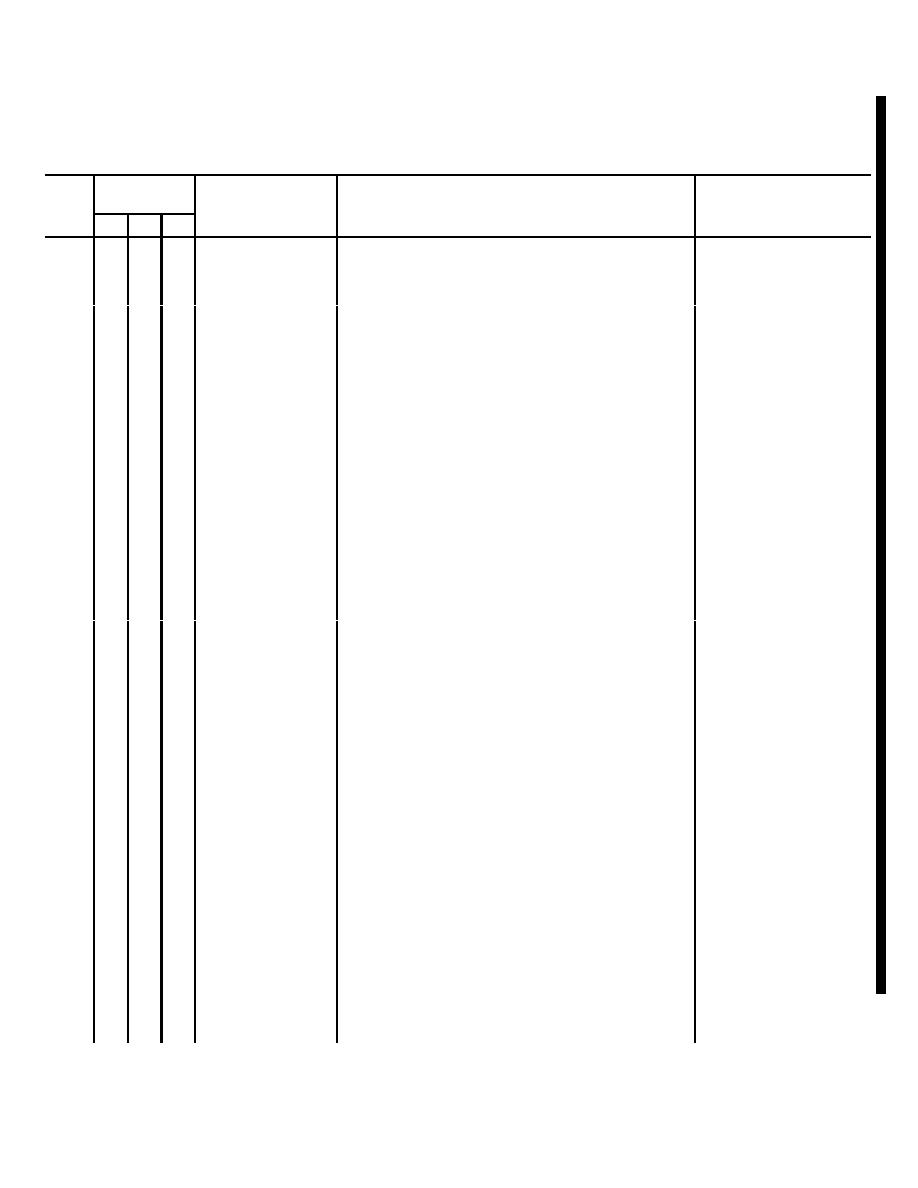

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

B - Before Operation

D - During Operation

A - After Operation

Procedures

Equipment is

Item

Interval

Item to be

Check for and have repaired

Not Ready/

No.

Inspected

or adjusted as necessary

Available if:

B

D

A

d. Check air cleaner indicators

for red warning indication. Empty

air cleaner dust compartments.

e. Check for loose, missing, or

damaged parts.

2.

Radiator

Check coolant level. Proper level

is 2 inches below filler neck.

3.

Control

Check operation of instrument panel

Panel Lamp

lamp. Replace if defective.

4.

Control and

Check for damaged control cables and

Instruments

gauges.

Monitor gauges for normal indication.

Normal indications are:

a. Engine

160 to 190F.

Water Temp-

erature

b. Engine

15 to 25 PSI idle, 40 to 60 PSI

Oil pressure is

Oil Pressure

full load.

below 10 psi.

c. Fuel

3 to 5 PSI.

Pressure

Gauge

d. Compres-

170 to 220F.

sor Oil

Temperature

e. Tachom-

1100 rpm idle, 2200 rpm full load.

eter-Hour-

meter

5.

Safety

Check operation by lifting lever

Valve fails to

Relief Valve

until air escapes.

reset or is

leaking air.

Change 1 3-9