TM 5-4310-354-14

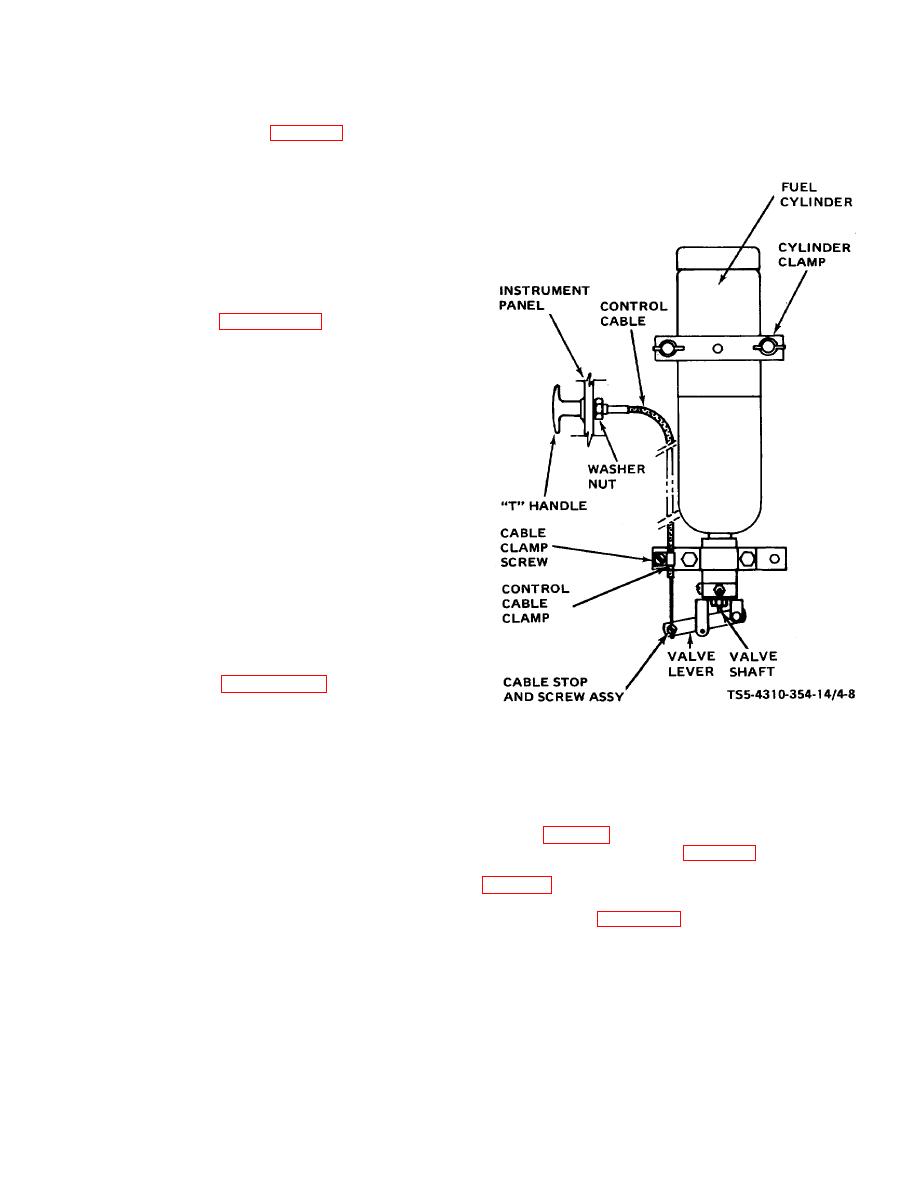

4-17. Quick Start Assembly Service . Service the

quick start assembly as shown in figure 4-8.

WARNING

DO NOT PUNCTURE OR MISHANDLE

FUEL CYLINDER.

THE CYLINDER

CONTAINS

AN

ETHER

BASE

MIXTURE WHICH IS EXTREMELY

TOXIC,

VOLATILE,

AND

COMBUSTIBLE.

STEP 1.

REFER TO FIGURE 3-14 AND REMOVE

THE FUEL CYLINDER.

STEP 2.

LOOSEN SCREW ON ACTUATING VALVE

LEVER CABLE STOP AND CONTROL

CABLE CLAMP SCREW. REMOVE THE

CONTROL CABLE FROM ACTUATING

VALVE ASSEMBLY.

APPLY A FEW

DROPS OF LUBRICATING OIL ON

CONTROL CABLE. CHECK OPERATION

OF CABLE BY PULLING AND PUSHING

THE QUICK-START ACTUATING HANDLE

ON INSTRUMENT PANEL. CHECK CABLE

FOR KINKS AND BREAKS.

STEP 3.

APPLY A LIGHT FILM OF LUBRICATING

OIL

ON

EXPOSED

PORTION

OF

MECHANICAL VALVE SHAFT.

STEP 4.

INSTALL CONTROL CABLE THROUGH

CABLE CLAMP, ATTACH TO LEVER AND

TIGHTEN SCREWS. ACTUATE CONTROL

CABLE A FEW TIMES TO CHECK FOR

ANY BINDING.

STEP 5.

REFER TO FIGURE 3-14 AND INSTALL

TS5-4310-354-14/4-8

FUEL CYLINDER, AS NECESSARY.

Figure 4-8. Quick start assembly service.

Section VI. TROUBLESHOOTING

4-18. Troubleshooting.

4-19. Organizational Maintenance Troubleshooting.

The Organizational Maintenance troubleshooting is

a. This

section

contains

troubleshooting

found in table 4-1. For troubleshooting within the scope

information for locating and correcting most of the

of Operator/Crew, refer to table 3-2 and for Direct

operating troubles which may develop in the air

Support and General Support Maintenance level,

compressor unit. Each malfunction for an individual

component, unit, or system is followed by a list of tests

each maintenance level is indicated in the Maintenance

or inspections which will help you to determine probable

Allocation Chart, Appendix C.

causes and corrective actions to take. You should

perform the tests/inspections and corrective actions in

NOTE

the order listed.

Before you use this table, be sure

b. This manual cannot list all malfunctions that may

you have performed all applicable

occur, nor all tests or inspections and corrective actions.

operating checks.

If a malfunction is not listed or is not corrected by listed

corrective actions, notify your supervisor.

4-11