TM 5-4310-354-14

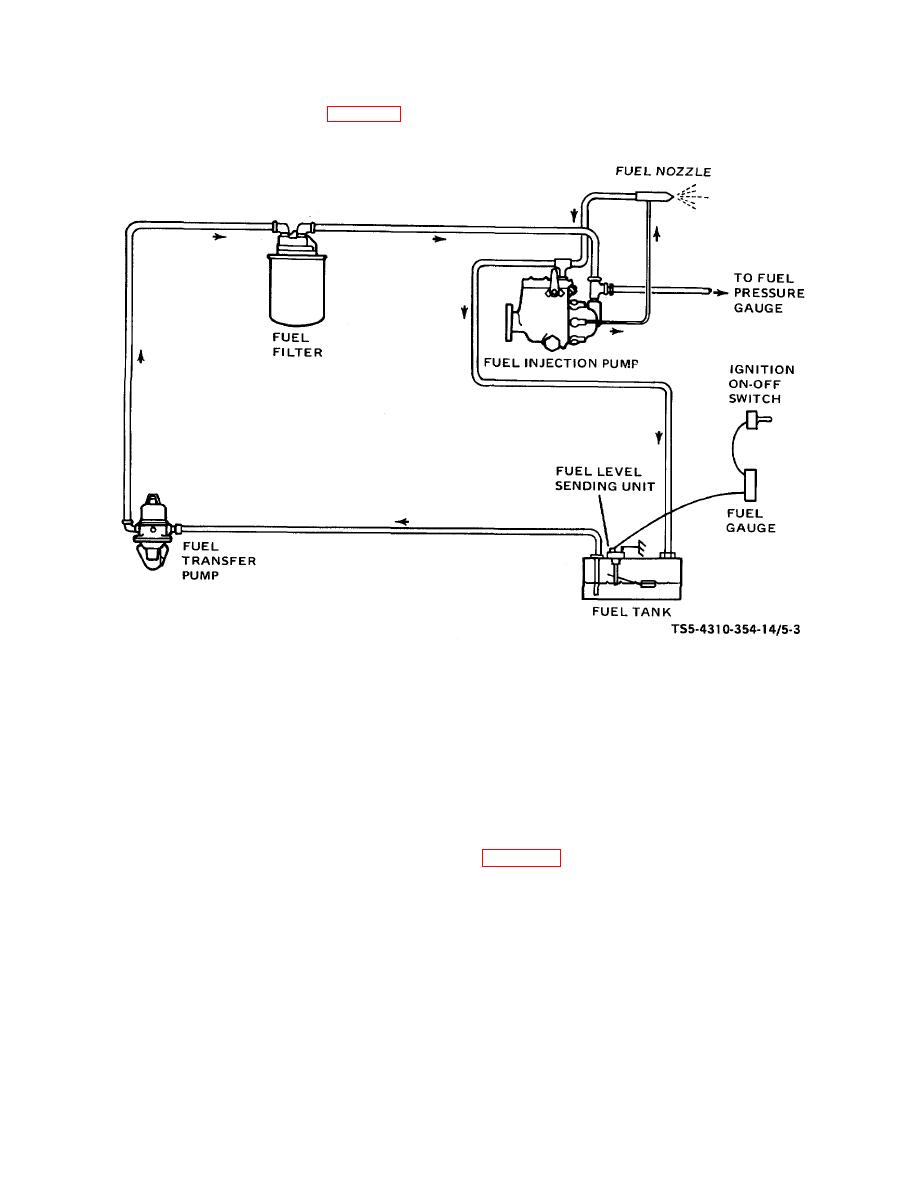

schematic diagram of the unit fuel system.

TS5-4310-354-14/5-3

Figure 5-3. Fuel system schematic diagram.

f. General Cleaning of Parts. In general, clean all

WARNING

metallic parts using cleaning solvent, Federal

Specification P-D-680, Type II. Clean non-metallic parts

Dry cleaning solvent, P-D-680, used

with a clean, lint-free cloth dampened with this same

to

clean

parts

is

potentially

solvent. Dry all parts thoroughly. Any cleaning that

dangerous

to

personnel

and

differs from this general method will be found in

property.

Avoid repeated and

instructions for that specific item.

prolonged skin contact. Do not use

near open flame or excessive heat.

g. Repair and Replacement Standards. Refer to

Flash point of solvent is 100 F-130 F

(38 C-59 C).

recommended by the manufacturer for engine and

compressor components.

5-13