TM 5-4310-354-14

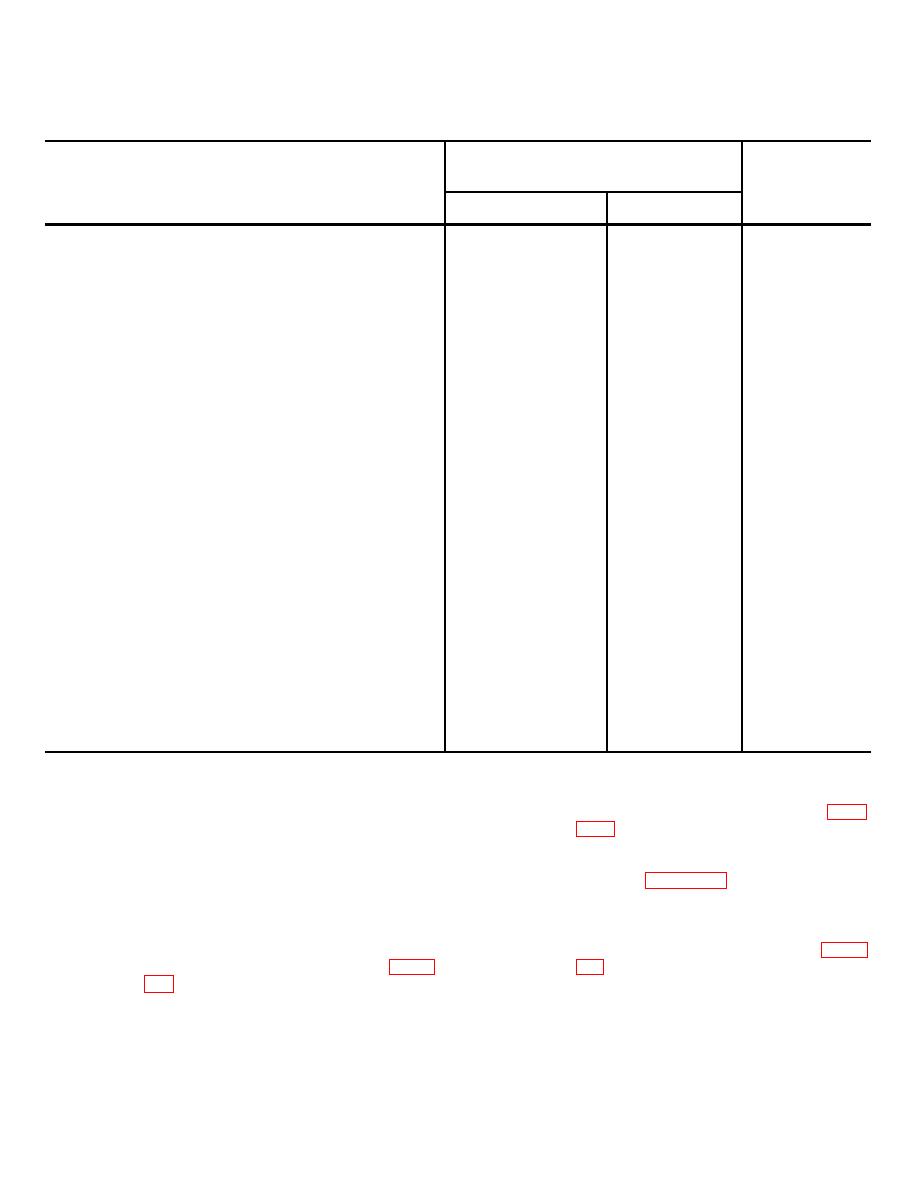

Table 5-2. Repair and Replacement Standards - Continued

Maximum

New parts

allowable

Component

wear/

clearance

Minimum

Maximum

COMPRESSOR - continued

Rotor:

Length .......................................................................................

9.123 in.

9.125 in.

(231.724 mm)

(231.775 mm)

Outside diameter .....................................................................

4.998 in.

5.000 in.

(126.949 mm)

(127.000 mm)

Bore ...........................................................................................

1.610 in.

1.611 in.

(40.894 mm)

(40.919 mm)

Blade slot width .......................................................................

0.1865 in.

0.1885 in.

(4.7371 mm)

(4.7879 mm)

Concentricity - outside diameter to bore

(total indicator reading, maximum material condition) ......

0.000 in.

0.004 in.

(0.0000 mm)

(0.1016 mm)

Rotor ends square with bore (total indicator

reading, maximum material condition).................................

0.000 in.

0.002 in.

(0.0000 mm)

(0.0508 mm)

Shaft:

Bearing journals ......................................................................

1.3782 in.

1.3786 in.

(35.0063 mm)

(35.0164 mm)

Rotor journal ............................................................................

1.608 in.

1.609 in.

(40.843 mm)

(40.869 mm)

Seal and coupling journal ......................................................

1.249 in.

1.250 in.

0.002 in.

(31.725 mm)

(31.750 mm)

(0.051 mm)

Concentricity of all journals (total indicator reading)

0.000 in.

0.001 in.

(0.0000 mm)

(0.0254 mm)

Blades:

Length .......................................................................................

9.110 in.

9.112 in.

(231.394 mm)

(231.445 mm)

Width .........................................................................................

1.248 in.

1.250 in.

1/16 in.

(31.699 mm)

(31.750 mm)

(1.588 mm)

Thickness .................................................................................

0.1841 in.

0.1871 in.

(4.676 mm)

(4.752 mm)

Ends square with length .........................................................

0.000 in.

0.001 in.

(0.0000 mm)

(0.0254 mm)

Section IV. REMOVAL AND INSTALLATION OF MAJOR COMPONENTS AND ASSEMBLIES

General. The major components covered in this

(2) Remove the hose reel assembly (para

5-8.

section are the compressor oil separator assembly,

blowdown valve assembly, air compressor assembly,

and the engine assembly.

(3) Remove air hoses from fittings on top of

separator (figure 4-22).

5-9.

Compressor Oil Separator Assembly.

(4) Attach a suitable lifting device to the

a. Removal.

compressor oil separator assembly and

remove from the unit as shown in figure

(1) Drain all oil from oil separator tank (figure

5-19