TM 5-4310-354-14

(1) Reassemble field coil assembly (40) into

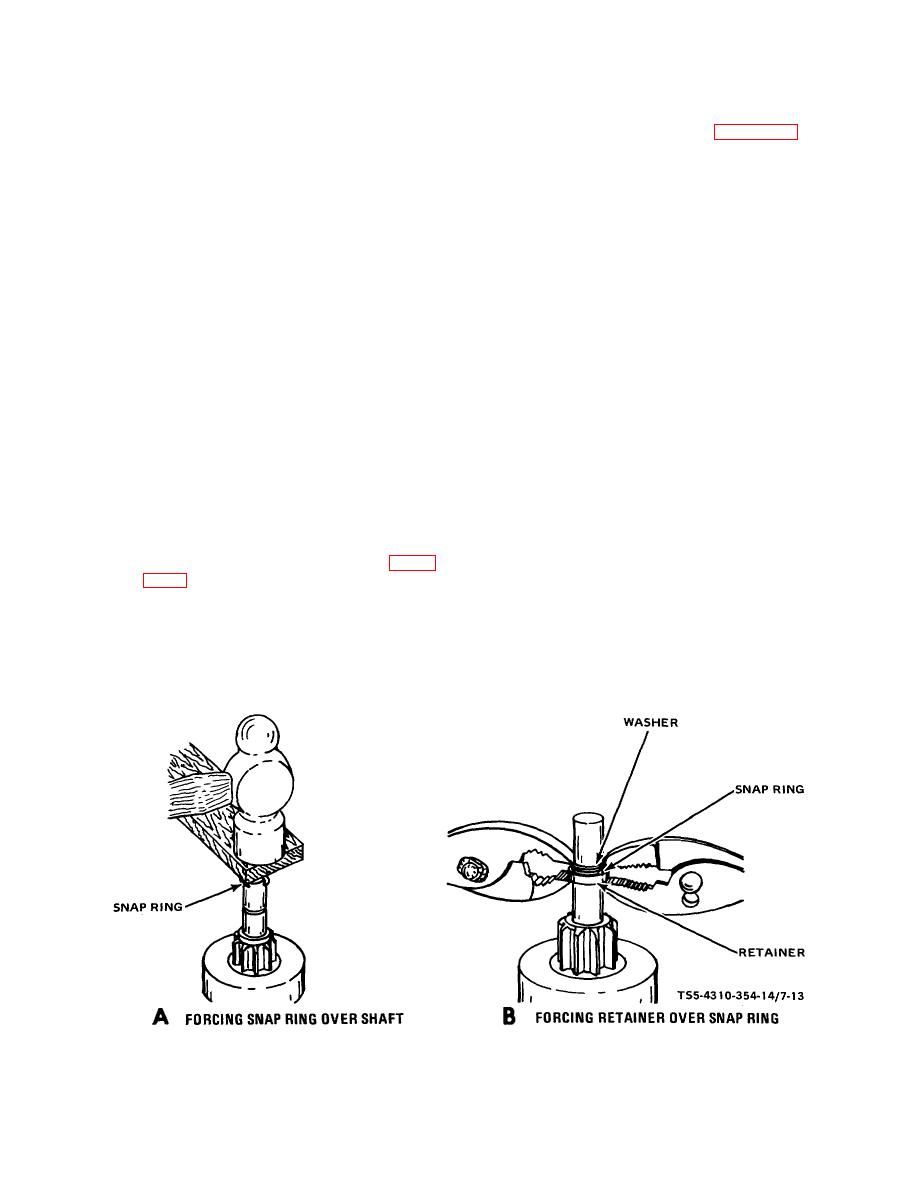

pliers as shown in figure 7-13. Remove

starter frame (41), assemble grommet

the washer. lubricate the armature (19)

(39), four pole shoes (38), and attach with

shaft and spline with Delco-Remy

four pole shoe screws (37).

Lubricant No. 1960954, or equivalent.

(2) If the two support packages (36) were

(6) Reassemble armature (19) into starter

disassembled, reassemble two ground

frame (41) and place washer (18) on

leads (35), brush holder supports (34),

armature shaft.

screws (33), lock washers (32), and nuts

(31).

(7) If disassembled, reassemble dowel pin

(17), bushing (12) into housing (11) and

(3) Reassemble two brush springs (30), two

bushing (10) into end frame (9). Lubricate

insulating brush holders (29), two ground

bushings (12, 10) with Delco-Remy

brush holders (28), attach with brush

Lubricant No. 1960954, or equivalent.

holder pins (27).

Reassemble four

brushes (26), two insulating brush screws

(8) Reassemble shift lever (16), lever stud

(25), and two ground brush screws (24).

(15), lock washer (14), and nut (13) in

drive housing (11).

Assemble drive

(4) Place clutch and drive assembly (23) on

housing (11) to starter frame (41) with shift

armature (19) shaft, place retainer (22) on

lever (16) engaged with groove of clutch

shaft with cupped surface facing the

and drive assembly (23).

retaining ring groove on shaft. Place the

retaining ring (21) on the end of the

(9) Reassemble commutator end frame (9) on

armature shaft. Using a piece of wood,

starter frame and install two through bolts

force the retaining ring over the shaft with

(8).

a light hammer blow as shown in figure

(10) Reassemble plunger (7) to shift lever (16)

the groove.

with lever pin (6). Assemble spring (5)

and solenoid switch (4) over plunger and

(5) Force the retainer over the retaining ring

attach solenoid switch (4) flange to drive

by placing a suitable washer over the

housing

shaft and squeeze retainer and washer

together with

TS5-4310-354-14/7-13

Figure 7-13. Installing clutch and drive assembly retainer and snap ring.

7-13