TM 5-4310-360-14

2-4.

Assembly and Preparation for

Use. continued.

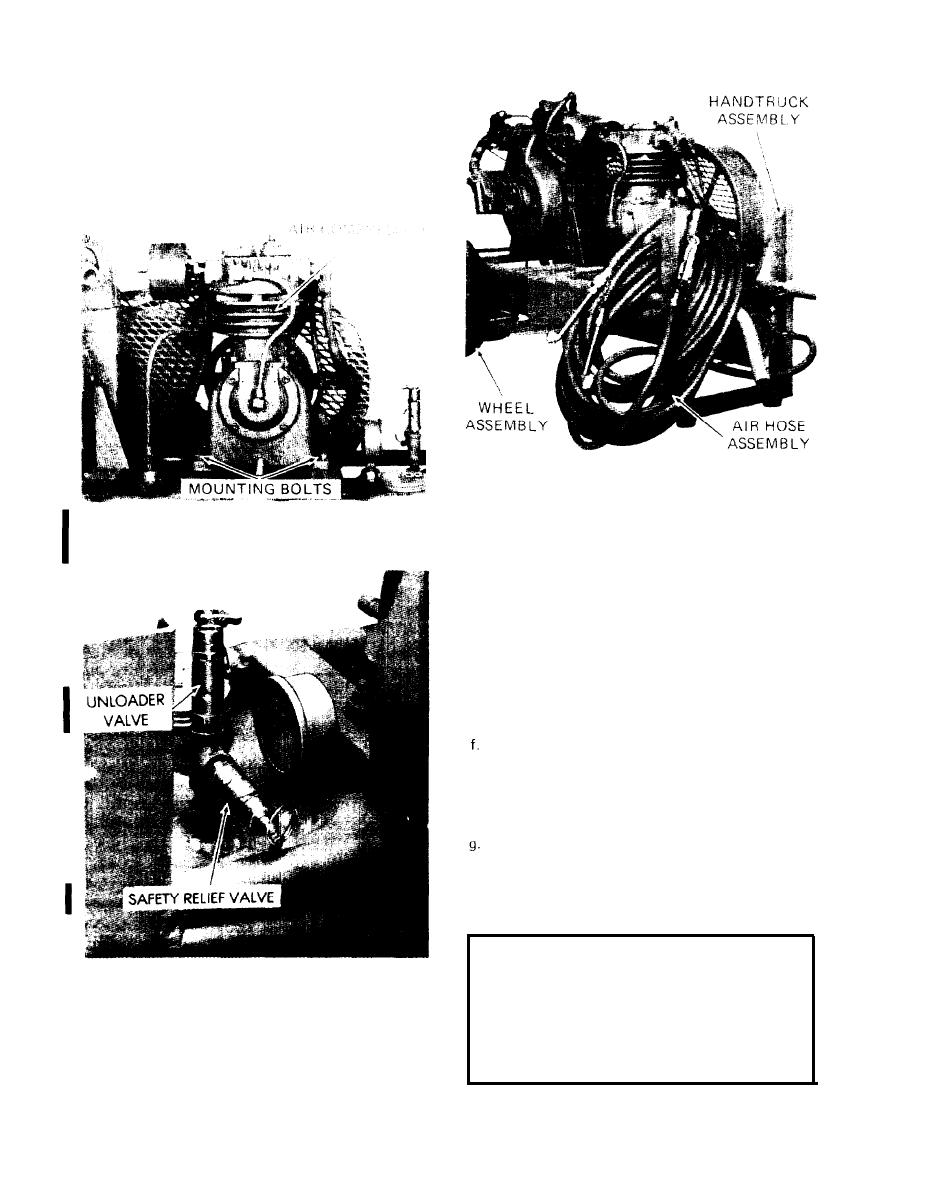

(3)

inspect the air Compressor for loose

mounting bolts, cracks, breaks and

other defects.

(7)

Check the contents of the crate

against the packing list to make sure

no items are missing.

(4) Inspect the unloader and safety

(8)

Correct all deficiencies or report them

relief valve for loose mounting.

to the proper authority.

Installation. The portable air compressor is

d.

delivered with an air hose assembly and gage

inflator. The air hose assembly is installed

directly in the end of the air receiver tank.

e.

Outdoor Installation. Avoid muddy, sandy

or dusty locations as a site for operation as

dirt and moisture shorten the life of all

moving parts.

Indoor Installation. If the compressor is to

be operated within a building or vehicle,

pipe the engine exhaust to the outside. Use

as few bends as possible in the exhaust line

and make sure all connections are tight.

Noise Hazard and Warning Signs. Signs con

forming to provisions of AR 385-30 will be

erected in the area to provide notification

of noise hazard in accordance with TB MED

251. The signs should read :

WARNING

NOISE HAZARD EQUIPMENT

(5)

Inspect the handtruck assembly for

cracks, breaks and other damage.

(6)

Inspect the wheel assemblies for

REQUIRED

cracks, breaks, insecure mounting and

alignment.

Change 1

2-8