TM 5-4310-367-14

I

*TOTAL TASK HOURS

*TOTAL TASK HOURS

INTERVAL

TASK-HOURS

INTERVAL

TASK-HOURS

0.5

D

Q

0.5

w

0.5

A

1.5

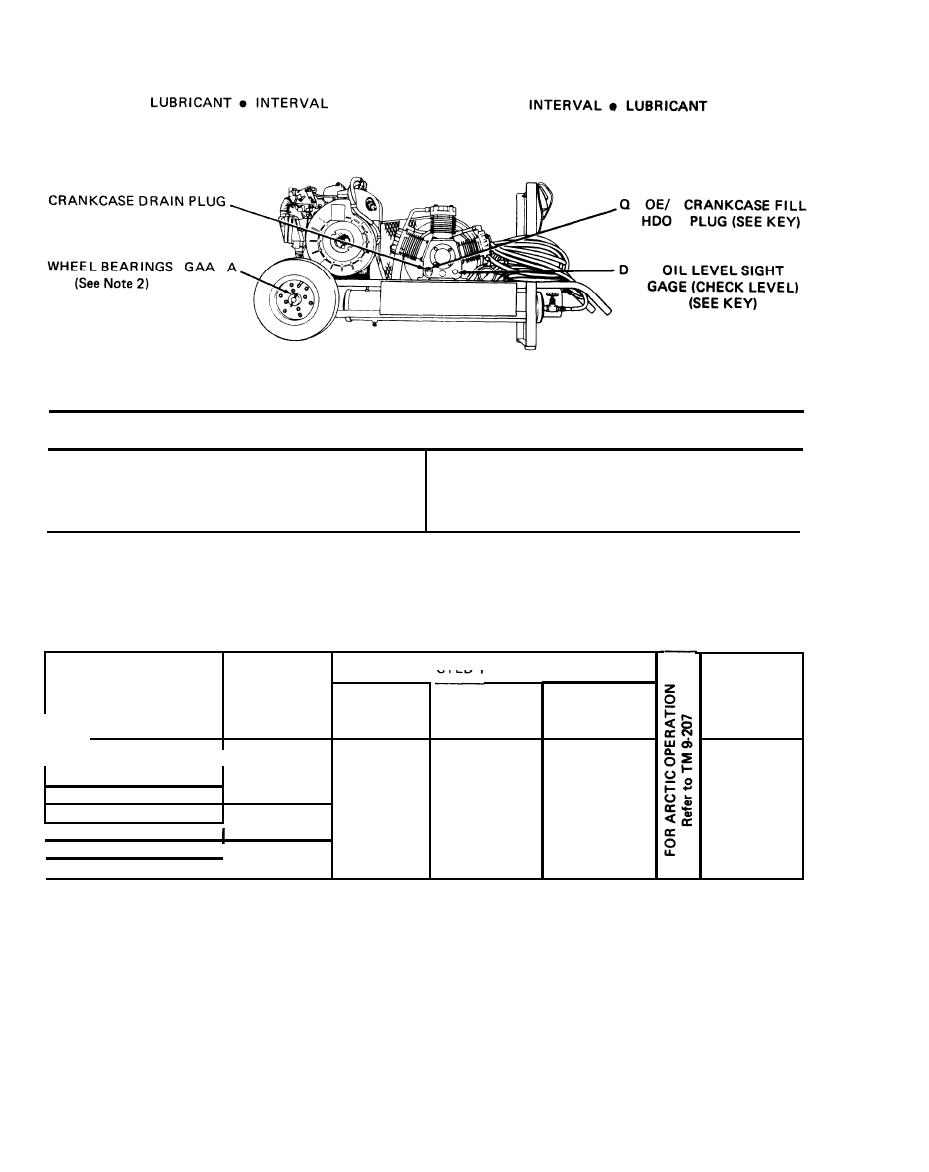

-KEY-

EXPECTED

TEMPERATURES

0F to -65F

Above +32F

+40F to - 1 0 F

0C

-18C to -50C

INTERVALS

Above

LUBRICANTS

CAPACITY

+ 5C to -23C

I

D 10 Hours

OE/HDO OIL, Engines,

or Daily

Heavy Duty

W 50 Hours

(MIL-L-2104C) Crankcase

OE/APG-PD-

OE/HDO 30

OEA/APG-PG.

1 qt. .946 liters

Q 250 Hours

OEA/APG-PD-1 Oil Engine

I

I

or Quarterly

Sub Zero

A 1000 Hours

SD2 Solvent

or Annually

CP-D-680

dry

cleaning

NOTES:

1.

FOR OPERATION OF EQUIPMENT IN PROTRACTED COLD TEMPERATURES BELOW -1OF -23C. Remove

lubricants prescribed in the key for temperatures above -1O F -23C. Clean parts with SOLVENT dry-cleaning

(P-D-680). Relubricate with lubricants specified in the key for temperatures below -10F -23C.

WHEEL BEARINGS. Every 1000 hours remove wheels, clean and inspect all parts, replace damaged or worn parts,

2.

repack bearings, and reassemble.

Figure 3-1. Compressor lubrication.

3-2