TM

5-4310-373-14

This task covers:

The inspection, removal and installation of the tube assemblies.

INITIAL SETUP

Equipment Condition:

Tools:

Compressor unit OFF

Main power OFF

Materials/Parts:

Soap Solution

Approximate Time Required (minutes):

Personnel Required:

50

1 Mechanic

REMARKS

ACTION

LOCATION/lTEM

Use soap solution. Check for leaks. Replace or repair as

1.

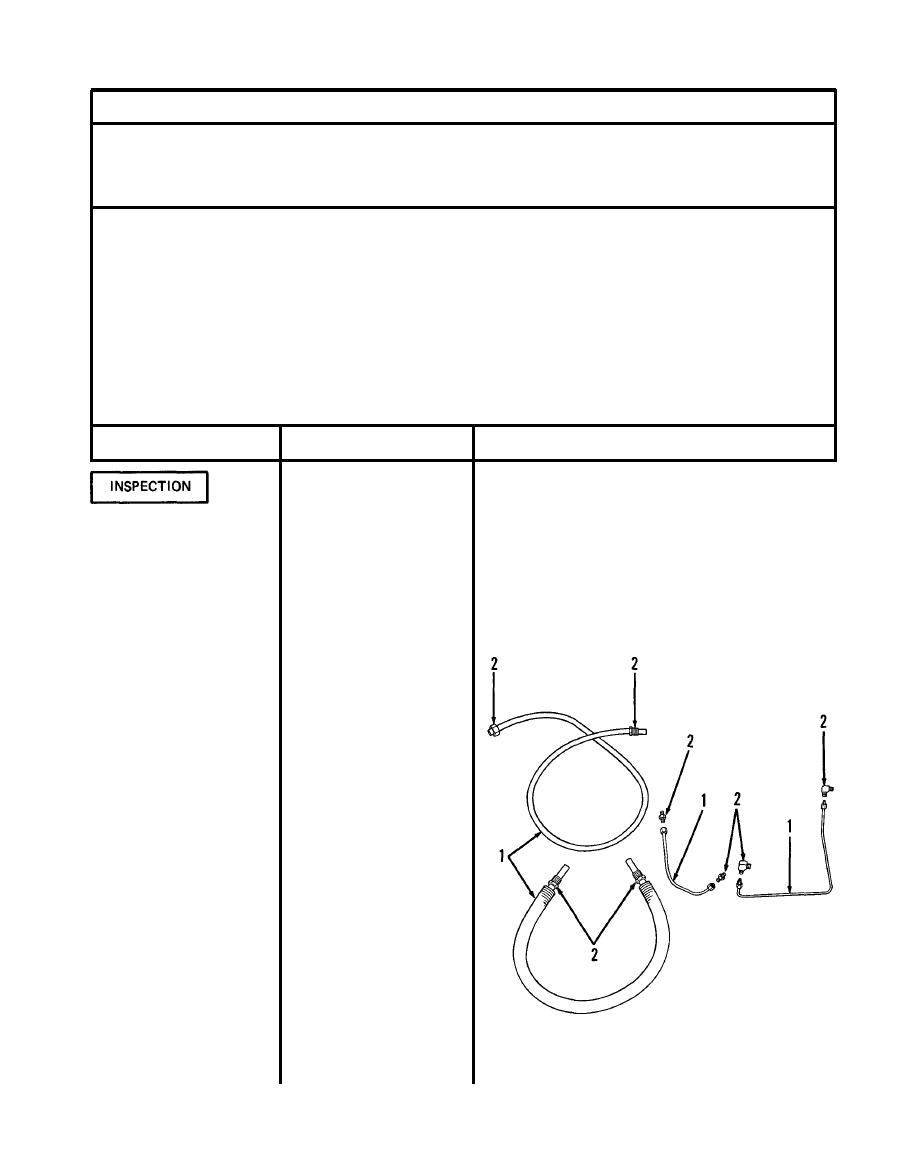

a. Inspect for leaks.

Air compressor tubing (1)

necessary.

b. Inspect tubing for kinks

or cracks.

c. Inspect tubing nuts.

Replace if

Tube fittings (2)

Inspect for thread damage.

2.

damaged.

Figure 4-60. Tubing assemblies

4-47