TM 5-4310-373-14

5-2. COMPRESSOR/ASSEMBLY

This task covers:

The assembly of the compressor.

INITIAL SETUP

Equipment Condition:

Tools:

Compressor removed and disassembled

Materials/Parts:

Gasket 5330-00-450-4130

Sealant

Oil OE-30

Approximate Time Required (minutes):

Personnel Required:

60

1 Mechanic

REMARKS

ACTION

LOCATION/TIME

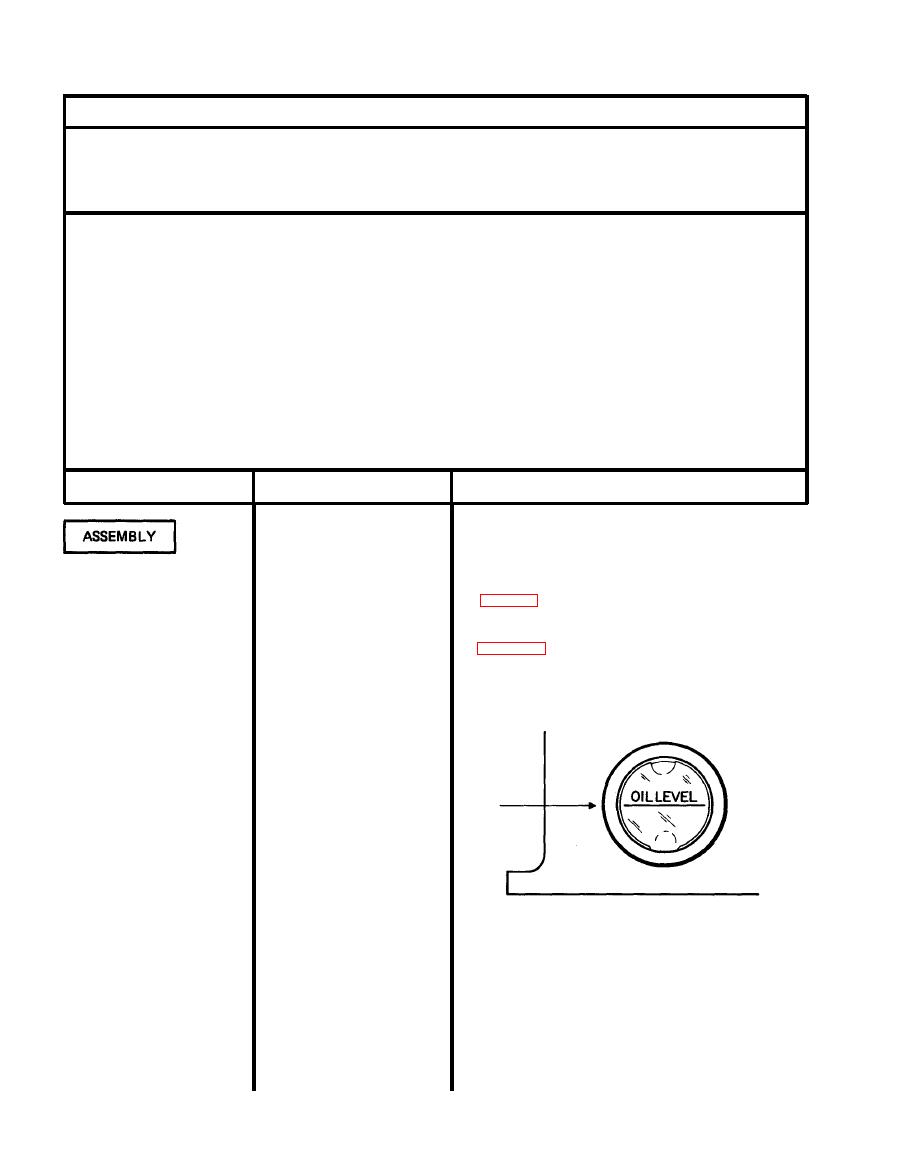

NOTE

Oil gage is to be replaced only

if it was noted to be defective

See para 5-1.

in disassambIy procedure.

1. Oil gage (1)

Indicating mark on gage must be horizontal to crankcase.

Coat edges with sealant and

See Figure 5-3.

press into crankcase with a

block of wood.

Install.

2. Plug (2)

Install.

3. Pipe (3)

Install.

4. Cap (4)

Install.

5. Plug (5)

Figure 5-2. Oil level gage

5-6