TM 5-4310-382-13

3-2. LUBRICATION INSTRUCTIONS - Continued.

Table 3-1. Lubrication Table

LUBRICATION TASK

INTERVAL

LUBRICANT

CAPACITY

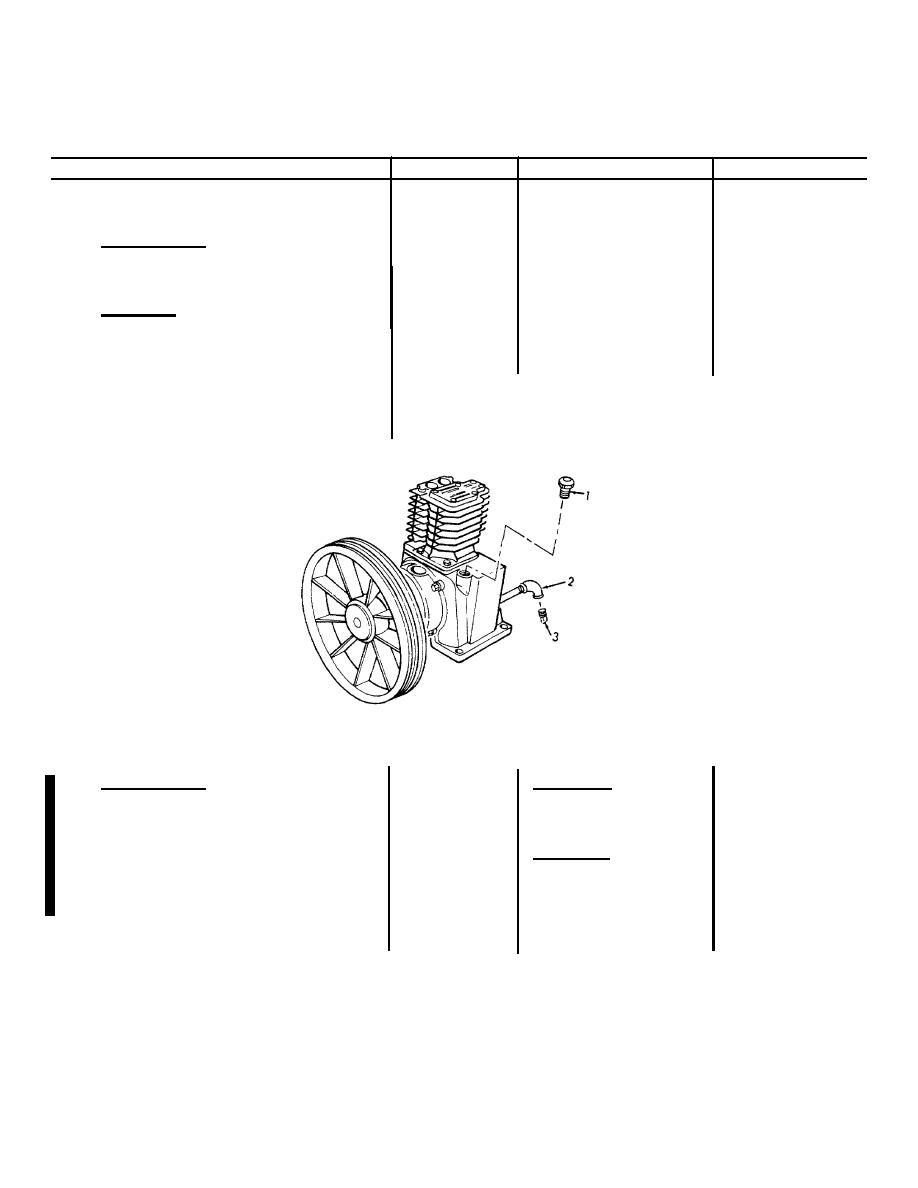

1. AIR COMPRESSOR

a. Oil Level Check.

10 hours

MIL-L-2104

1-1/2 quarts

Check level of compressor oil. Add oil as

(weekly)

(1.4 liters)

necessary until sight gage is half full.

b. Oil Change.

After first

MIL-L-2104

1-1/2 quarts

While oil is still warm, remove compressor

100 hours (3

(1.4 liters)

oil filler cap (1), place container under oil

months),

drain (2), remove plug (3) and drain com-

then every

pressor oil. When oil is removed, install

500 hours

plug (3), discard oil and fill compressor

(12 months).

with clean compressor oil until sight gage is

half full. Install oil filler cap. Perform oil

level check in a. above.

2. GASOLINE ENGINE

Above 32F

a. Oil Level Check.

5 hours

3 pints

Remove oil gage rod and check oil level

(0C) operation:

(1.4 liters)

indicated on rod. Add oil as indicated.

SAE 10W30 Grades

Replace oil gage rod, wait 10 seconds,

SC, SD, or SE

Below 32F

remove oil gage rod and inspect oil level

(0C) operation:

again. Adjust level as needed.

SAE 5W-30, Grades

SC, SD, or SE

3-2 Change 1