TM 5-4310-382-13

3-35. RELIEF VALVES, AIR GAGE, DRAIN COCK, AND AIR VALVE.

This task covers:

a. Removal

b. Cleaning

c. Inspection

d. Installation

INITIAL SETUP

Tools Required

Tool Kit, General Mechanic's

Materials Required

Brush, Medium Bristle (item 4, Appendix E)

Solvent, Dry Cleaning (item 2, Appendix E)

Cloth, Lint-Free (item 3, Appendix E)

Compound, Anti-seize (item 7, Appendix E)

Equipment Condition

Engine shut down and cool.

Pressurized air drained from system.

Air hose inflator gage removed (see para 3-34).

a. Removal.

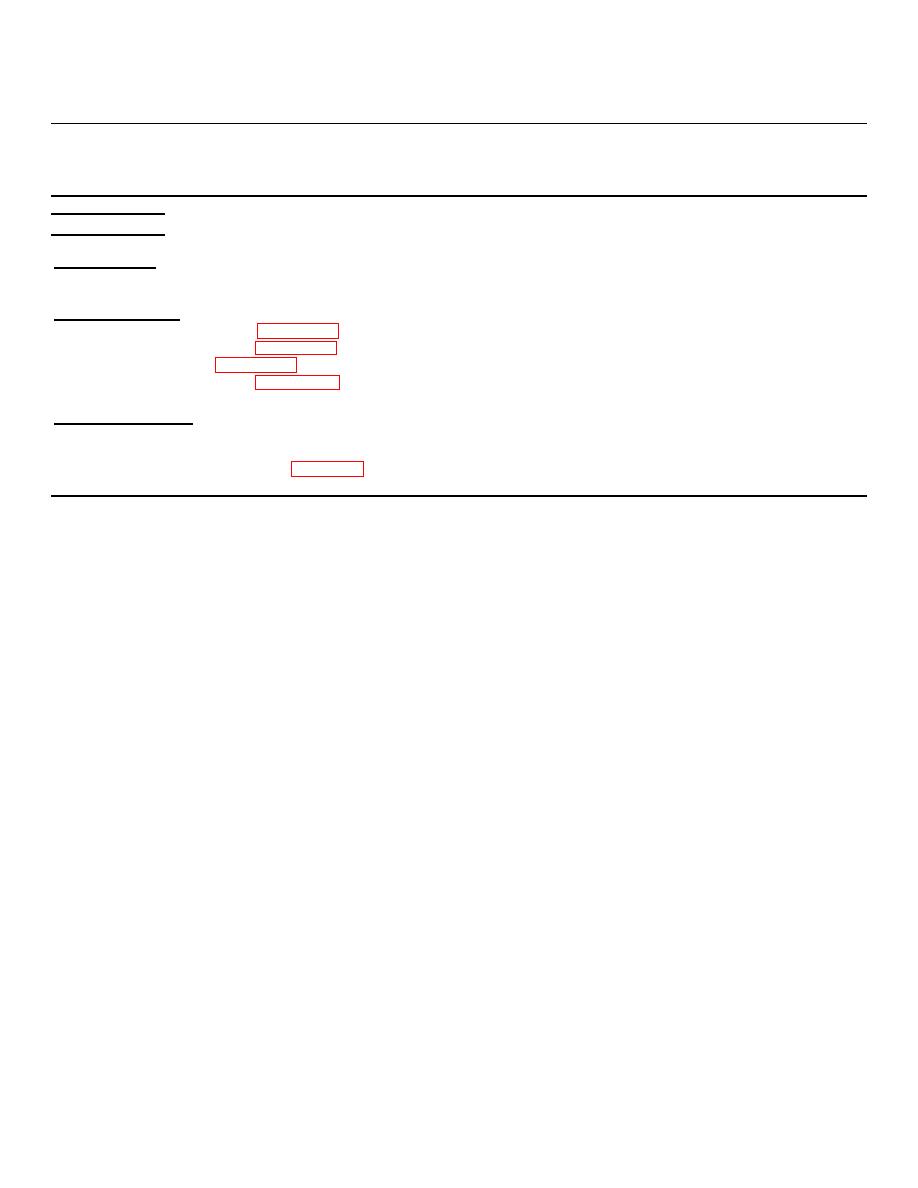

(1) Disconnect tube (1) from elbow (2).

(2) Remove clamp (26), hose (25), and barbed fitting (27) from tee (3).

(3) Remove elbow (2), tee (3), and nipple (4) from pilot valve (5).

(4) Remove valve (5), nipple (6), bushing (7), and elbow (8) from cross (12).

(5) Remove air gage (9) and bushing (10) from cross (12).

(6) Remove relief valve (11) from cross (12).

(7) Remove cross (12), nipple (13), elbow (14), and nipple (15) from air tank (16).

(8) Remove nipple (19), elbow (20), bushing (18), air valve (21), and nipple (22) from air tank (16).

(9) Remove relief valve (24) from top of compressor (23).

(10) Remove drain cock (17) from tank (16).

3-82