TM 5-4310-384-13

CHAPTER 2. OPERATING INSTRUCTIONS

SECTION I. DESCRIPTION AND USE OF OPERATOR'S CONTROLS AND INDICATORS

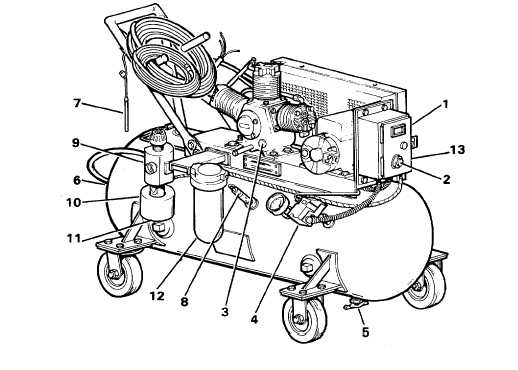

2-1.

OPERATOR'S CONTROLS AND INDICATORS.

Key

Name

Location

Function

On

Location

Main power switch

Main switch box

Turns electric power to the compressor on

and off.

1

ON/OFF switch

Starter enclosure

Start and stop compressor.

2

RESET button

Starter enclosure

Push to reset after overload condition has

tripped the protective relay on magnetic

starter.

3

Oil level sight

glass

Compressor

crankcase

Shows oil level in crankcase.

4

Pressure gage

Air tank

Shows air pressure in tank.

5

Drain cock

Bottom of air tank

To drain air and water from tank.

6

Shutoff valve

End of tank

To close off air tank when air hose has to

be removed.

7

Inflator gage

Handle assembly

To check pressure of the system being tested.

8

Safety relief valve

Air tank

Releases air pressure in tank above 200 psi.

Can be manually checked by pulling ring.

9

Regulator/filter

Air tank

Regulates air discharge pressure.

10

Heater block

Regulator/filter

Prevents moisture from freezing.

11

Petcock

Regulator/filter

Drains regulator/filter bowl.

12

Dehydrator

Air tank

Dries air before discharge.

13

Thermostat

Starter enclosure

Regulates temperature.

Operator's Controls and Indicators

2-1