TM 5-4310-384-13

Table 2-1. Operator's Preventive Maintenance Checks and Services (Continued)

B

-

Before Operation

D

-

During Operation

A

-

After Operation

W

-

Weekly

4

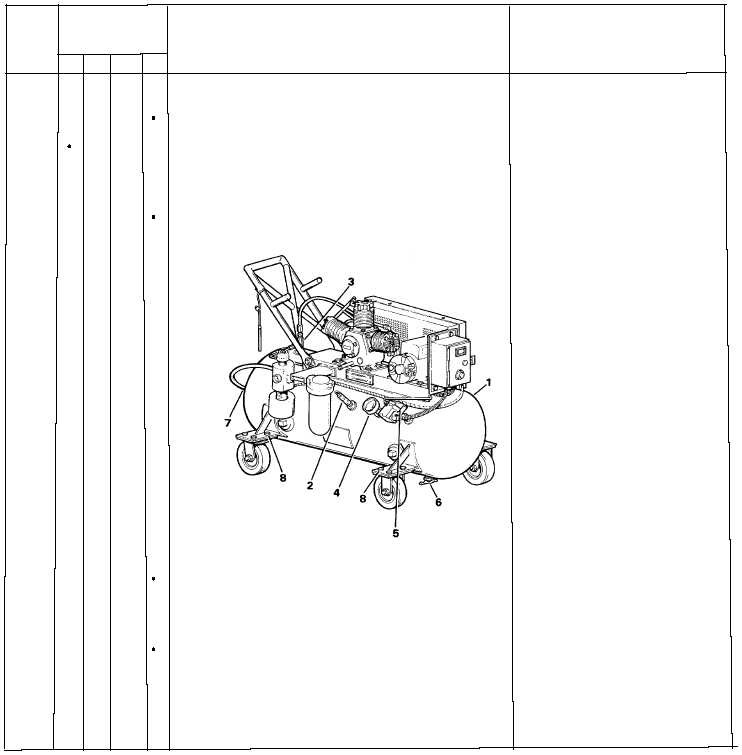

AIR RECEIVER SYSTEM

a.

Inspect air tank (1) for any signs of damage.

Damaged tank.

b.

Inspect fittings on air tank for secure attachment:

Not securely attached.

safety valve (2), check valve (3), pressure gage

(4), pressure switch (5), drain cock (6), and

globe valve (7).

c.

Check mounting bolts (8) on casters for tightness.

Loose bolts.

5

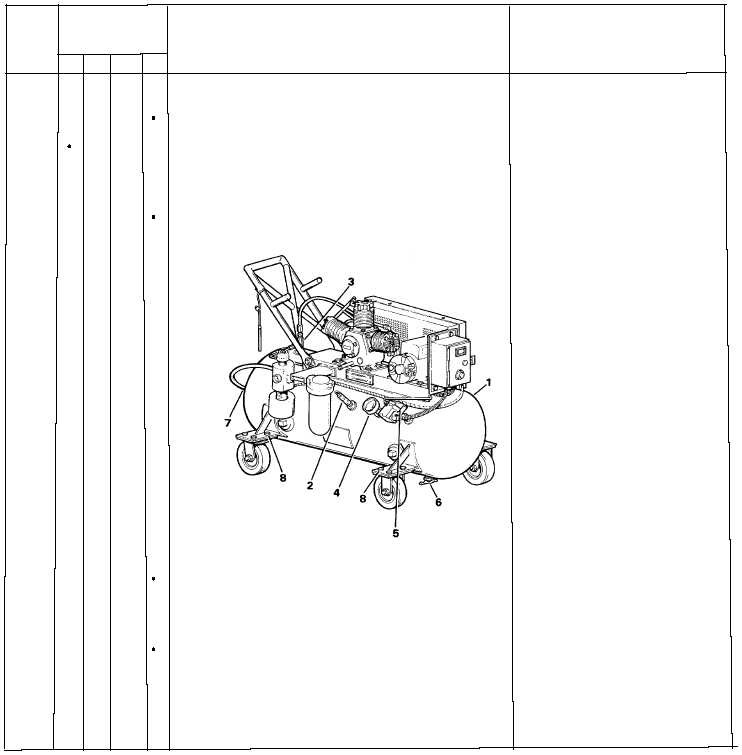

AIR DISCHARGE SYSTEM

a.

Inspect air hose (1) for cracks, splits, or other

Cracked, split or

signs of deterioration. Check for secure attachment

deteriorated air hose.

to shutoff valve (2).

Shutoff valve not

securely attached.

b.

Inspect hose (3) for cracks, splits or other

Cracked, split or

signs of deterioration.

deteriorated hose.

ITEM

NO.

INTERVAL

ITEM TO BE INSPECTED. PROCEDURE:

EQUIPMENT NOT

READY/AVAILABLE IF:

B D A W

2-6