TM-5-4310-389-14

5-10

TIMING GEARS (ENGINE)

DESCRIPTION

This task covers: Replace. Repair.

INITIAL SETUP

Tools:

Equipment conditions:

Screwdriver, metric feeler gauge

The engine must be cold.

Materials/parts:

Cloth, Lint-free, item 9 Appendix E

REPLACE REPAIR

NOTE

Do not change the setting of oil nozzle unless required. With hot engine running at idling, an oil flow

to pad of rocker arm must be just noticeable. An excessive oil flow can lead to higher oil

consumption.

a.

Overhauling the Rocker Arm Bracket.

1.

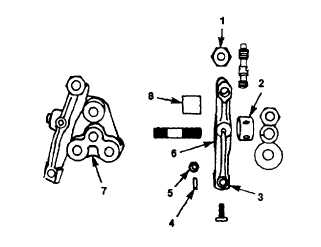

Ensure rod ends are tightly seated and free from wear (figure 5-82).

Figure 5-82. Push Rod, Push Rod Tube, and Tappet

5-52