TM-5-4310-389-14

3-5

LUBRICATION OF COMPRESSOR UNIT . For proper care and maintenance of the compress unit, using the

correct viscosity of oil and adhering to the maintenance procedures is of vital importance. It is required that the oils used

for the compressor be restricted to those that conform to MILL-17331 (Normal Temperature, 2190 TEP) and MIL-H-

17672 (Arctic Temperature, 2135TH). Engine oil must conform to specification MIL-L,2104.

3-6

OIL CAPACITIES . The oil capacity of the compressor is 4.2 quarts (4.0 liters), and the engine is 4.75 quarts (4.52

liters).

3-7

MAINTENANCE ON A NEW ENGINE AND COMPRESSOR.

a

Engine.

1.

V-Belt Retention. At the end of 50 hours running.

2.

Change Oil. At the first oil change, the following jobs are also due.

a)

Clean lube oil filter.

b)

Retighten engine mounting bolts.

c)

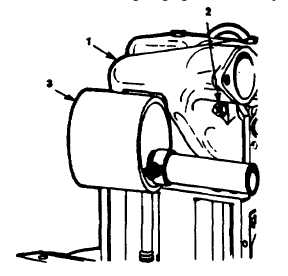

Check connections for air intake (1) and exhaust (3) manifolds to cylinder heads for tightness and

retighten bolts (2), if necessary. See figure 3-4.

d)

Check valve clearance (paragraph 3-23); readjust, if necessary.

Figure 3-4. Intake and Exhaust Manifold Securing Bolts

Change 1 3-3