TM 5-4310-393-14

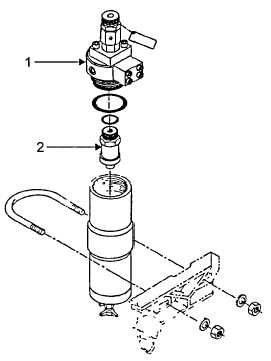

3.16.3. OIL/WATER SEPARATOR.

This task covers A Service

Tools:

Materials/Parts:

Tool Kit, General Mechanic's Set

Lint-free Cloth NSN 7920-00-9281

Wrench, Strap (NSN 5120-01-192-9406)

Grease, Halo Carbon NSN9150-00-754-2760

Detergent, Non-ionic NSN7930-00-282-9699

Equipment Conditions'

Equipment secured

System Purged of Pressure

Intake Filter Removed

A.

Service.

1.

Removing the Sintered Filter.

a.

Disconnect the inlet and outlet tubes from

the separator head.

b.

Unscrew and remove separator head (1)

using the strap wrench

c.

Unscrew the sintered filter element (2) from

the separator head Remove the center screw to remove

the filter element

2.

Cleaning the Sintered Filter.

a.

Clean the element using hot soapy water.

Blow dry with compressed air.

3.

Reassembling the Oil/water Separator.

a.

Coat the threads and O-rings and the

threads of the filter element with a thin coat

of halo carbon grease.

b.

Dry the inside of the filter housing with a

clean cloth and check for corrosion before reinstalling

the filter element. If excessive corrosion is found, refer

to Unit Maintenance.

c.

Reinstall

in

reverse

sequence

of

disassembly.

FIGURE 3-17. OIL/WATER SEPARATOR

3-29