TM 5-4310-452-14

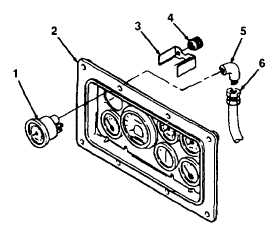

4-51. DISCHARGE PRESSURE GAGE AND FUEL PRESSURE GAGE REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

Initial Setup:

Equipment Conditions:

Tools/Test Equipment:

• Engine off.

• General mechanic's tool kit

• Left door assembly open,

• Battery cables disconnected (see paragraph

4-57).

NOTE

Use this task to replace discharge pressure gage or fuel pressure gage. Discharge pressure

gage is shown.

a. REMOVAL

1.

Remove window (see paragraph 4-55).

2.

Remove hose (6) from elbow (5), Remove elbow

from discharge pressure gage (1).

3.

Remove 2 knurled nuts (4) and retainer (3) from

discharge pressure gage (1).

4.

Remove discharge pressure gage (1) from indicator

panel (2).

b.

INSTALLATION

1.

Position discharge pressure gage (1) in place in indicator panel (2).

2.

Install retainer (3) and 2 knurled nuts (4) on discharge pressure gage (1).

3.

Install elbow (5) and hose (6) on discharge pressure gage (1).

4,

Install window (see paragraph 4-55),

FOLLOW-ON TASKS:

•· Connect battery cables (see paragraph 4-57).

•· Close left door assembly.

TA505482

4-97