TM 5-4310-452-14

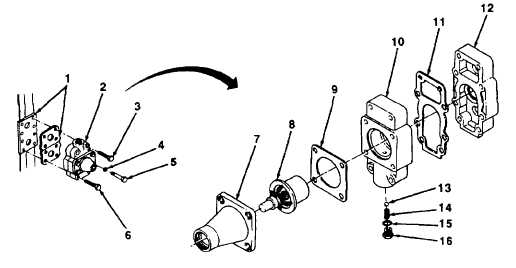

5-36. OIL TEMPERATURE BYPASS VALVE MAINTENANCE (Con't).

NOTE

Clean outer and inner bodies of gasket material.

3.

Separate outer body (10) from inner body (12) and remove gasket (11). Discard gasket.

4.

Remove plug (16), spring (14), and ball (13) from outer body (10).

5.

Remove preformed packing (15) from plug (16). Discard preformed packing.

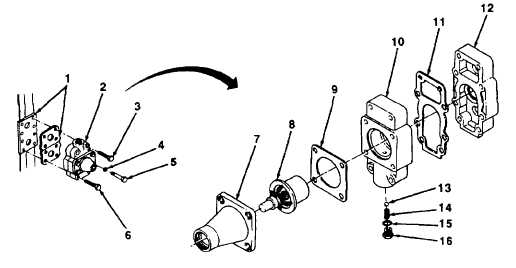

c. ASSEMBLY

1.

Position new preformed packing (15) on plug (16).

2.

Place ball (13) and spring (14) in plug (16) and install plug in outer body (10).

3.

Install thermostat (8) in outer body (10).

4.

Position new gasket (11) on inner body (12), Aline mounting holes of outer body (10) and place on inner body.

5.

Position new gasket (9) on outer body (10). Place access cover (7) on outer body.

d. INSTALLATION

NOTE

Access cover, outer body, and inner body are not secured together at this time. Hold together

for mounting purposes.

1.

Position 2 new gaskets (1) and oil temperature bypass valve (2) in place on oil cooler and install 4 screws (5) and

washers (4).

2.

Install 2 screws (3) and 2 screws (6) in oil temperature bypass valve (2).

FOLLOW-ON TASKS:

• Install compressor oil lines and fittings (see paragraph 4-86).

• Fill oil compressor (see LO 5-4310-452-14).

TA505610

5-90