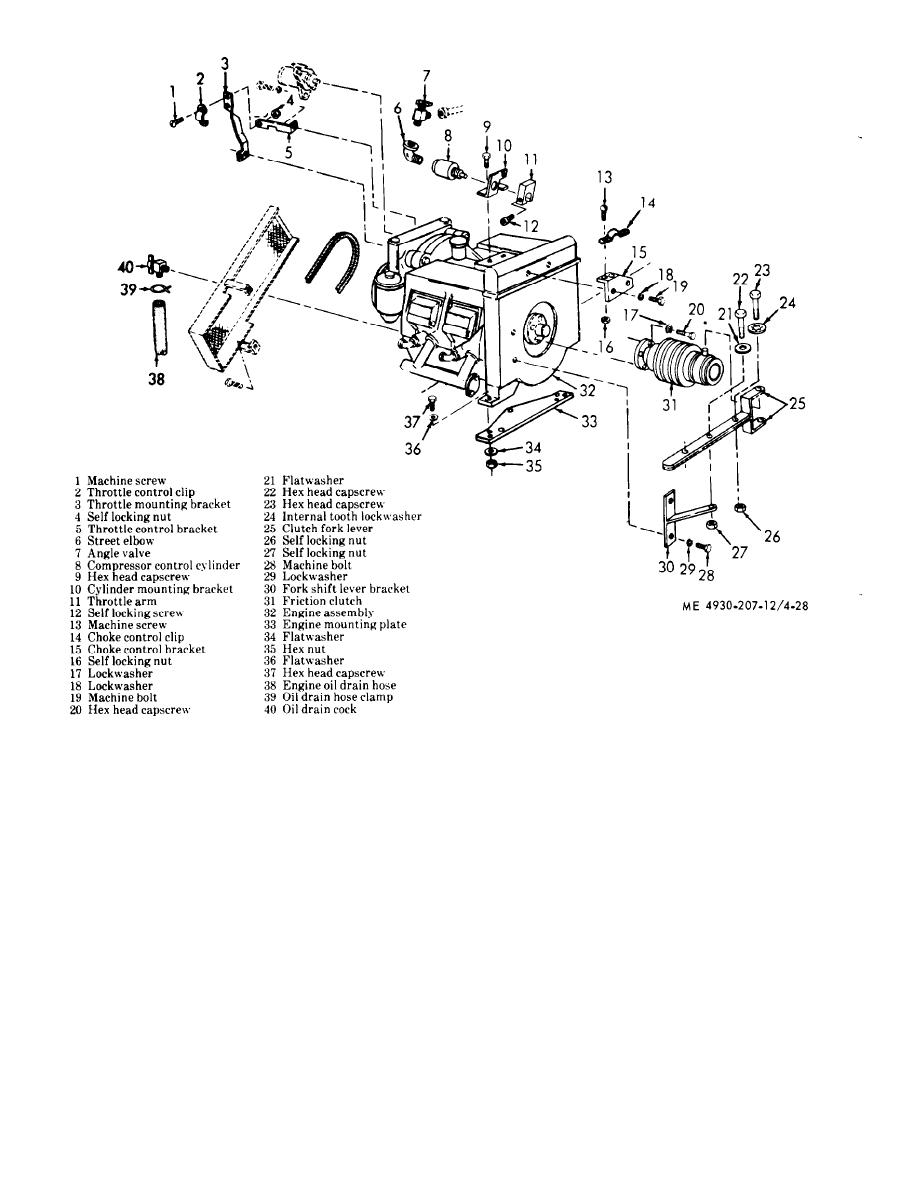

Figure 4-28. Engine and clutch, removal and installation.

(2) Position fork lever (25) on friction clutch (31)

(3) Remove four hex screws (20) and lockwashers

and lever bracket (30) and install washers (21 and

(17) securing the friction clutch (31) to the engine

24), capscrews (22 and 23) and self locking nuts (26

crankshaft and remove the friction clutch.

and 27).

c. Cleaning, Inspection and Repair.

(3) Adjust the clutch (a above).

(1) Clean the friction clutch by flushing with

(4) Install the compressor drive belt, and belt

kerosene. Blow dry with clean, moisture free com-

guard (para 3-17).

pressed air.

(2) Inspect clutch balls for wear or flattening.

4-38. Engine Assembly

Inspect entire clutch for damaged or worn parts.

a. Removal.

(3) Replace a defective clutch.

(1) Remove the lubrication unit enclosure as-

d. Installation.

sembly (para 4-6).

(1) Position friction clutch (31, fig. 4-28) on

(2) Use a suitable container and drain the engine

engine crankshaft and secure with four lockwashers

crankcase by opening draincock (40), remove clamp

(17) and capscrews (20).

4-36