TM

5-4930-207-34

CHAPTER 6

REPAIR OF TRAILER COMPONENTS

S e c t i o n I. SERVICE BRAKES

to trailer frame. Remove other air filter in a

6-1. General

similar manner.

The trailer service brakes are the scavenger type

actuated by a diaphragm-type air chamber. Each

assembly of air filter in numerical sequence.

brake has two wheel cylinders secured to the

c. Inspection.

backing plate. The wheel cylinders are actuated

(1) Inspect filter body for cracks, breaks,

hydraulically to give an equal pressure to all

stripped threads, and other damage.

brakeshoes. The air relay valve controls the trailer

(2) Inspect spring for distortion or fatigue.

brakes and automatically applies the trailer brakes

d. Repair.

in event the trailer separates from the towing

(1) Repair is made by replacement.

vehicle.

(2) Replace parts supplied in kit.

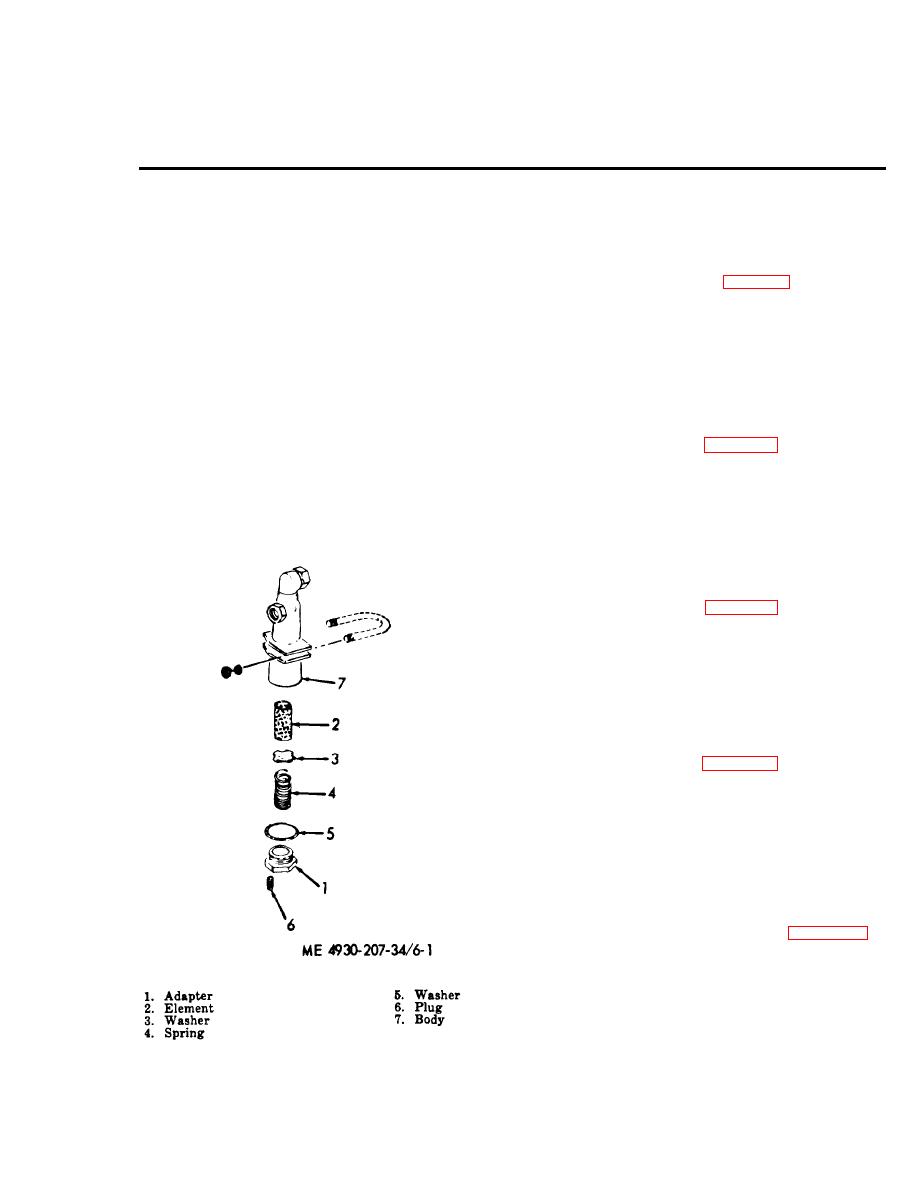

e. Reassembly. Refer to figure 6-1 and reassem-

6 - 2 . Air Filters

ble the air filter in reverse of removal.

a. Removal. Disconnect two lines from air fil-

f. Installation. Refer to TM 5-4930-207-12 for

ter, remove two nuts and U-bolt holding air filter

correct installation of air filter.

6-3. Hydraulic Master Cylinder

a. Removal. TM 5-4930-207-12 provides re-

m o v a l instructions for the hydraulic master

cylinder.

semble the hydraulic master cylinder in numerical

sequence,

c. Inspection.

(1) Inspect body for dents, stripped threads,

and other damage.

(2) Inspect spring for distortion or fatigue.

d. Repair. Replace defective parts.

e. Reassemble. Refer to figure 6-2 and reas-

semble the hydraulic master cylinder.

f. Installation. Refer to TM 5-4930-207-12 and

install the hydraulic master cylinder.

6-4. Brakeshoes and Linings

a. Removal. Refer to TM 5-4930-207-12 and

remove the brakeshoes.

b. Disassembly. Disassemble the brakeshoe as

illustrated in numerical sequence in figure 6-3.

c. Inspection.

(1) Inspect the brakeshoes for cracks and

breaks.

(2) Inspect linings for wear and evidence

of grease or hydraulic fluid having penetrated the

linings.

Figure 6-1. Air filter, disassembly and reassembly.

6-1