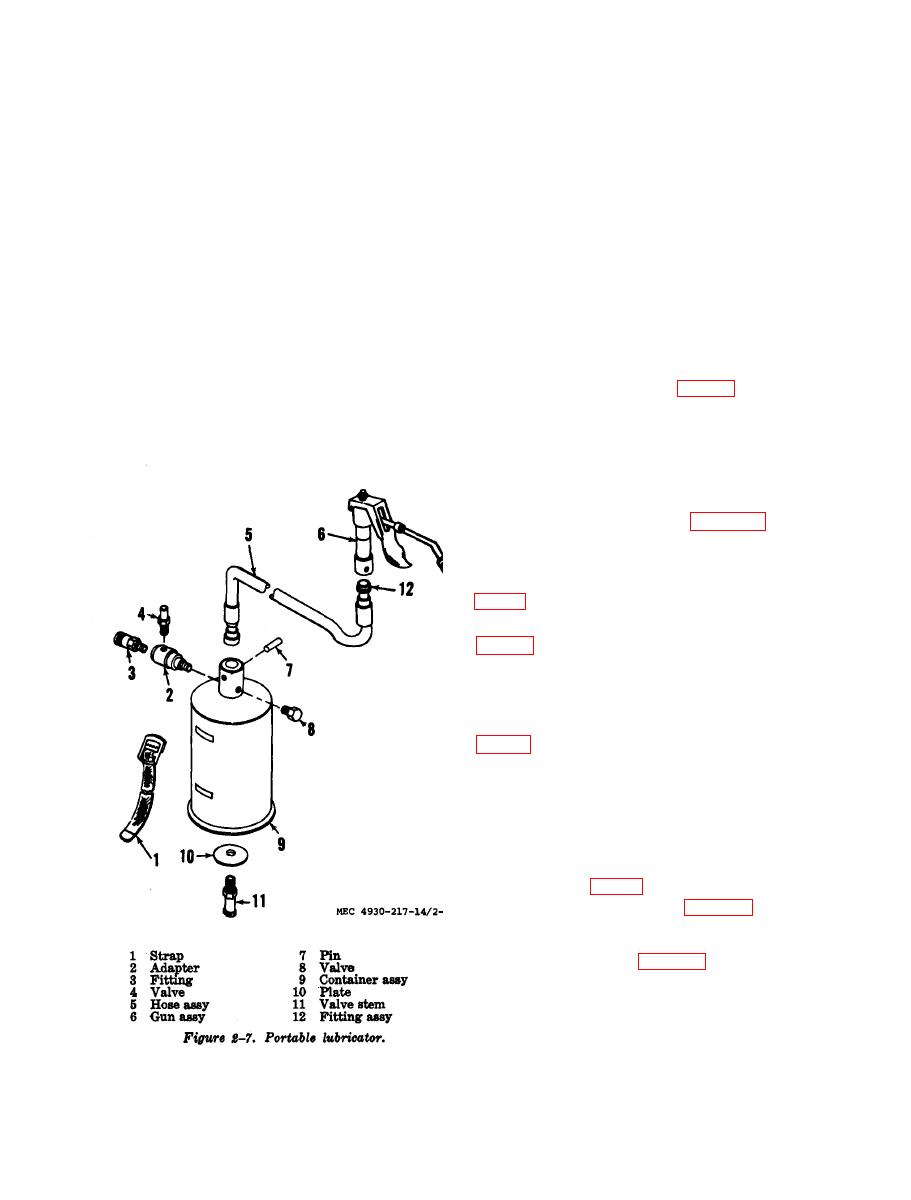

(b) Remove pin (7) and insert hose

2-28. Fire Extinguisher

assembly (5) into connector as far as it will

a. Description. The portable carbon dioxide

go. Replace pin (7) to its full length and check

type fire extinguisher is suitable for electrical

to be sure hose assembly (5) fits tight in con-

and flammable liquid fires.

nector.

b. Operation. Remove fire extinguisher from

(c) Fill the lubricator with grease

its location; break the seal, operate the con-

until the indicator valve (4) indicates when

trol valve, and direct the stream at the base of

the lubricator is full. Do not overfill.

the flame.

(d) Insert other end of hose (5) into

c. Maintenance. For maintenance of the fire

the body of the booster valve and screw the

extinguisher, refer to TM 5-687.

swivel fitting assembly (12) hand tight.

(e) Open the air relief valve on the

2-29. Heat Diverter Controls

booster valve until grease flows in a steady

stream. Close the relief valve. The unit is

now ready for use.

heat diverter levers (22, fig. 2-3) ducts gas

either to a heat reservoir beneath the lubri-

Note. The portable lubricator need not be

cant container or directly to atmosphere.

refilled with air each time grease is completely ex-

pelled. The air charge will last about a year.

b. Operation in Cold Weather.

(1) In cold weather operation, duct ex-

haust gas to the heat reservoir.

(2) Start the engine (para 2-11) and

close all doors on the lubricating unit.

(3) Allow the engine to run for about ten

minutes with the air tank drain valve (44,

fig. 2-3) open.

(4) Close the air tank drain valve (44,

before using the lubricating pump.

a. General. Use the alcohol dispenser (6,

dispenser is used to inject alcohol into the air

line leading to the pump to prevent condensate

freezeup. The alcohol dispenser is equipped

with an. eight-ounce capacity metal bowl and

a needle valve, which controls the flow of al-

cohol.

b. Operation (fig. 2-8).

(1) Shut down the unit (para 2-12).

(2) Remove plug handle anti fill with

alcohol. Reinstall handle.

(3) Start engine (para 2-11).

(4) During operation, inspect sight gage

frequently and refill when necessary.

(5) Open needle valve approximately

turn.