TM 5-4930-218-14

a soap bubble solution to detect any leaks.

(3) Inspect the valve for cracks, damaged

threads, and faulty seating surfaces. Inspect the

mating seating surfaces on the valve plate for scoring

or damage. Replace damaged parts.

a. Removal.

(4) Inspect all other parts for cracks, distortion,

(1) Remove the enclosure from the lubricating

damaged threads, and other damage; replace

and servicing unit (para 4-17).

damaged parts.

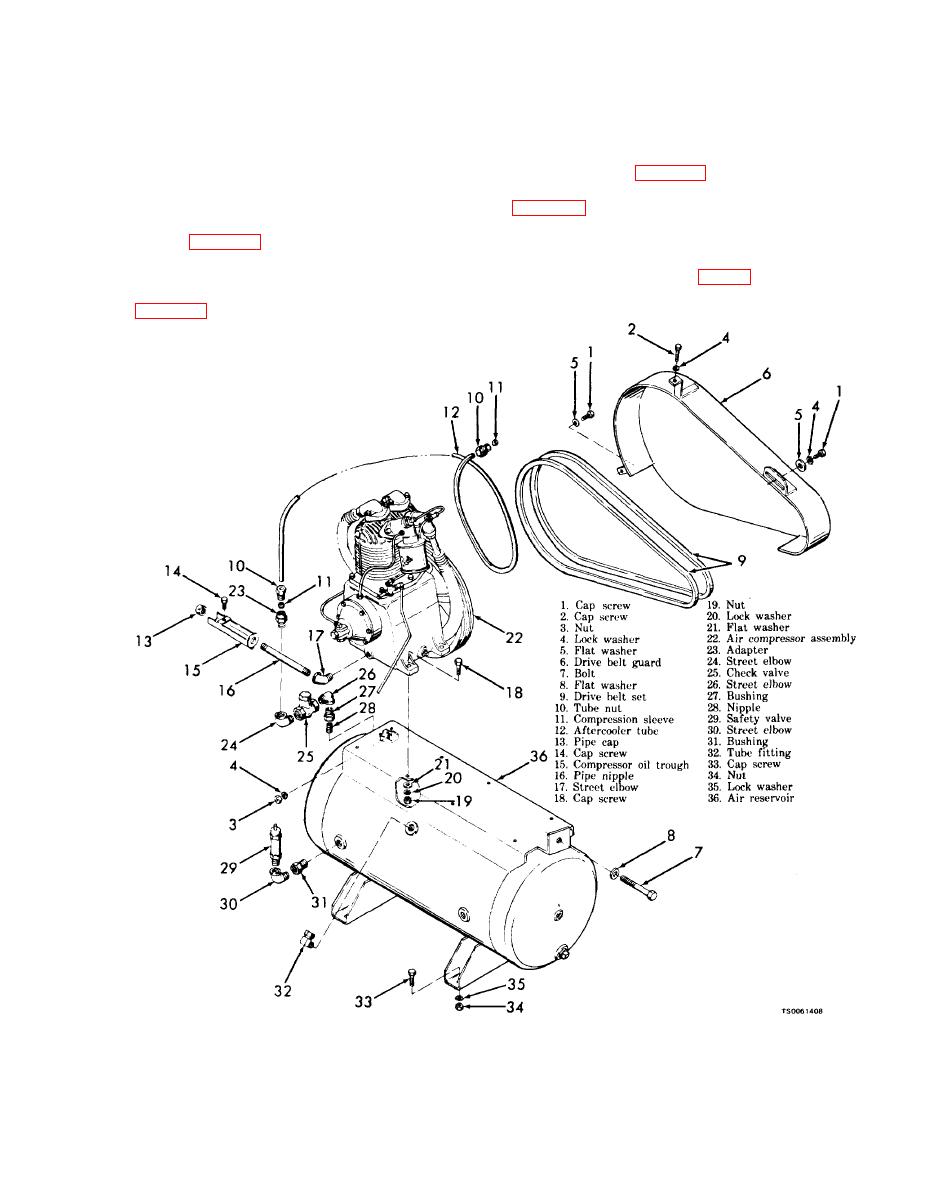

(2) Remove the compressor drive belts and guard

c. Reassembly and lnstallation.

WARNING

(1) Reassembly is the reverse of disassembly.

Drain all air from the air system

Refer to figure 4-8. Use new gaskets to minimize the

before disconnecting piping.

possibility of leaks. Make sure all seating surfaces

(3) Loosen tube nuts (10, fig, 4-9) and disconnect

are clean and free from foreign particles.

the aftercooler tube (12) that interconnects the air

(2) Install the alcohol dispenser as shown in

compressor (22) and the air reservoir (36).