stem of the griphandle and pry down on the ejecting pin extension.

c. Preparing for Storage. To prevent internal parts of the drill from rusting while in storage, follow the procedure

outlined below:

(1) Flush the drill thoroughly with cleaning solvent; then flush with light oil to lubricate all internal parts.

(2) Wedge a cloth plug into the air inlet and exhaust openings to prevent dust from entering the tool while in

storage.

(3) Store the wood drill and auger set in its appropriate place in the front tool box.

Section IV. ROCK DRILL

146. Description

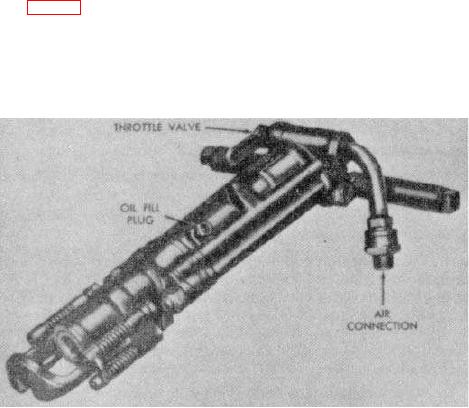

The pneumatic rock drill (fig. 66) is a piston-rotary-type unit primarily designed as a hard rock drill. However, it is

equally efficient in soft and medium formations as well. Two rock drills are supplied with the air compressor, and the

following attachments are included: four each of 2-foot, 4-foot and 6-foot drill steels and 40 each of 1-5/8-inch, 1 3/4-inch,

1 7/8-inch and 2-inch detachable rock bits. When not in use, the rock drills and attachments are stored in the compressor

side tool box.

Figure 66. Pneumatic rock drill.

147