LUBRICATION

LO5-4310-350-12

ORDER

15 JULY 1975

COMPRESSOR, AIR, TANK MOUNTED, ELECTRIC MOTOR DRIVEN,

15 CFM AT 175 PSI CHAMPION MODEL NO. HR5-8M-3

NSN 4 3 1 0 - 0 0 - 5 3 7 - 8 8 7 6

Reference: Federal Supply Catalog C9100-IL

Intervals are based on normal hours of operation. Adjust to

Clean parts with SOLVENT, dry-cleaning, Type II (SD-2).

compensate for abnormal operation and severe conditions.

Dry before lubricating.

During inactive periods, sufficient lubrication must be per-

formed for adequate preservation.

Drain crankcases while the lubricant is still warm from previ-

ous use. Replenish and check level when cool.

* The time specified is the time required to perform all services

at the particular interval.

* TOTAL MAN-HR.

* TOTAL MAN-HR

I

INTERVAL

MAN-HR

MAN-HR

INTERVAL

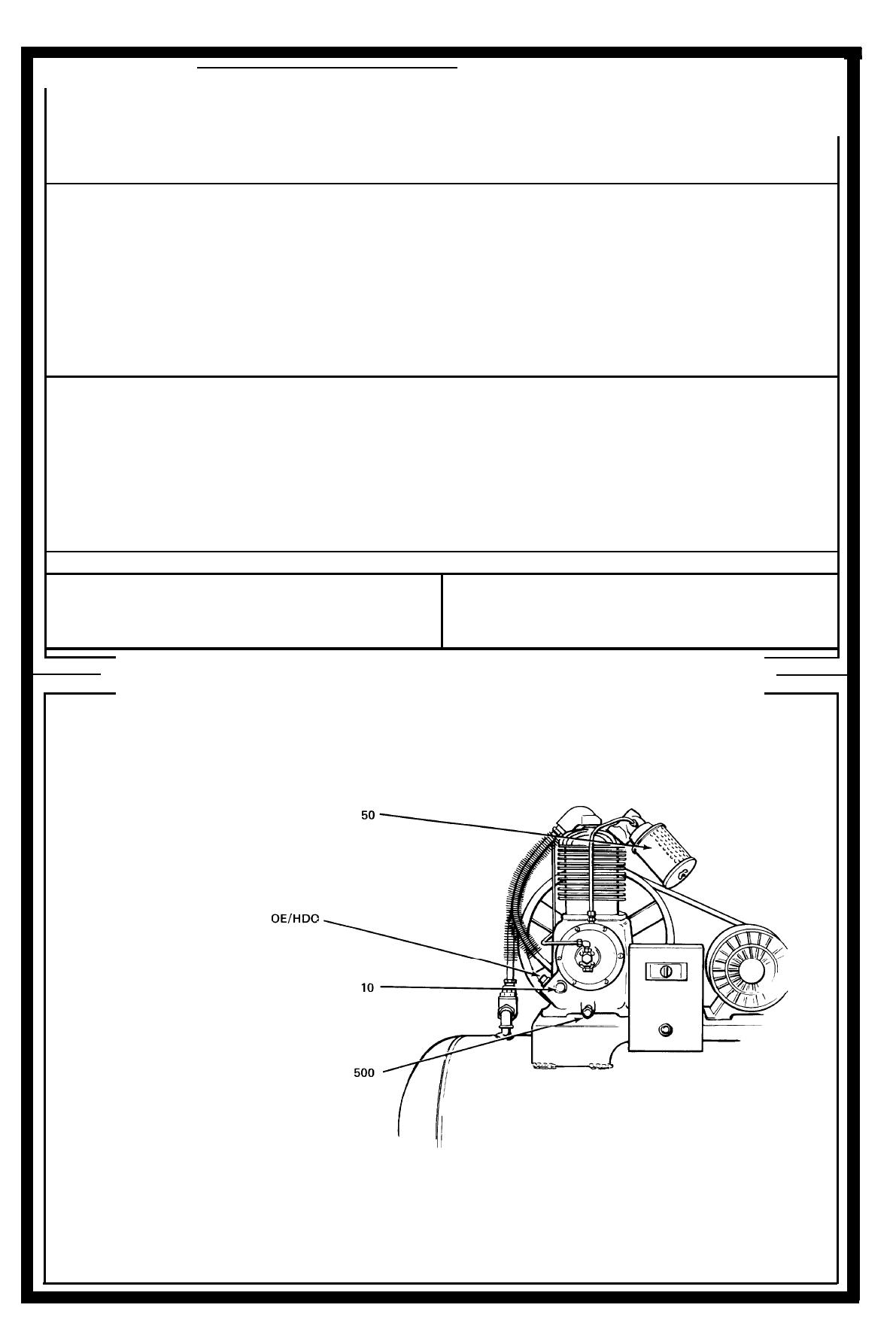

10

0.25

500

0.1

50

0.25

FOLD

FOLD

LUBRICANT

INTERVAL

q

Air Intake Muffler.

Disassemble, Clean

and Reassemble.

Oil Filler Cap

(See Key)

Oil Level Sight Gage

(Check Level)

Oil Drain Cap

(Drain and Refill)

(See Note 1 )