TM 5-4220-233-14

CAUTION

The storage cylinders should only be filled with dry, oil free nitrogen per BB-N-411.

Failure to follow this precaution may result In contamination of the Servicing Unit

storage cylinders.

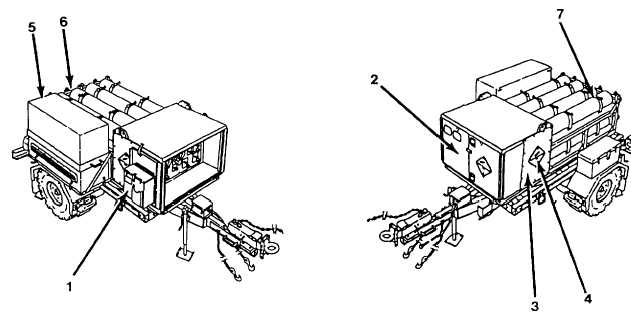

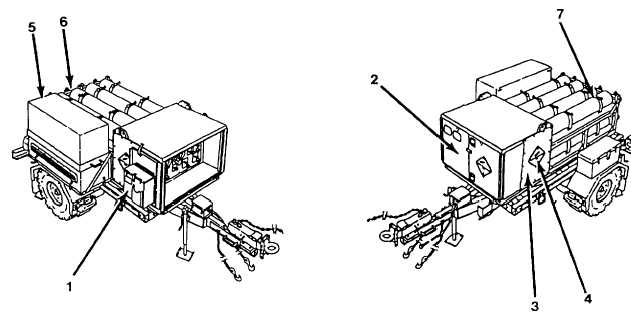

(6) Connect nitrogen pressure source to recharge port (5).

(7) Pressurize the storage cylinders with nitrogen per BB-N-411 to a pressure of 300 psi.

(8) Record pressure reading at pressure source and date, store document with recorded

pressure with other documents of Servicing Unit.

(9) Close eight cylinder valves (3).

(10)

Close recharge valve (4) and disconnect nitrogen pressure source from recharge port.

(11)

Slowly open recharge valve (4) to allow residual pressure in Compressed Gas System to

vent.

(12)

Close eight 1/4-turn ball valves (2) and recharge valve (4).

(13)

Install dust cap on recharge port (5).

Figure 4-57. Preparation for Storage.

b. Preparing Body Assembly for Storage.

(1) Ensure protective coverings installed at both ends of fill hoses and hoses are stowed in body

tool box (1).

(2) Ensure drain plugs are installed at the bottom of body tool box (1) and control compartment.

(3) Close and secure Compressed Gas System tool box (1).

(4) Ensure the appropriate documents (breathing air certification, test date, storage cylinder

nitrogen pressure, etc.) are secured in document holder.

(5) Close and secure control compartment front doors (2).

(6) Install control compartment side panels (3).

(7) Ensure all four non-flammable gas placards (4) are installed and secured.

(8) Ensure trough (5) is secured to trough mounting base.

(9) Ensure two cylinder holddown brackets (6) are secured and adjustable stops on eachbracket

are tight against base of each cylinder.

(10)

Ensure all sixteen cylinder clamps (7) are properly secured.

4-103