TM 5-4310-335-14

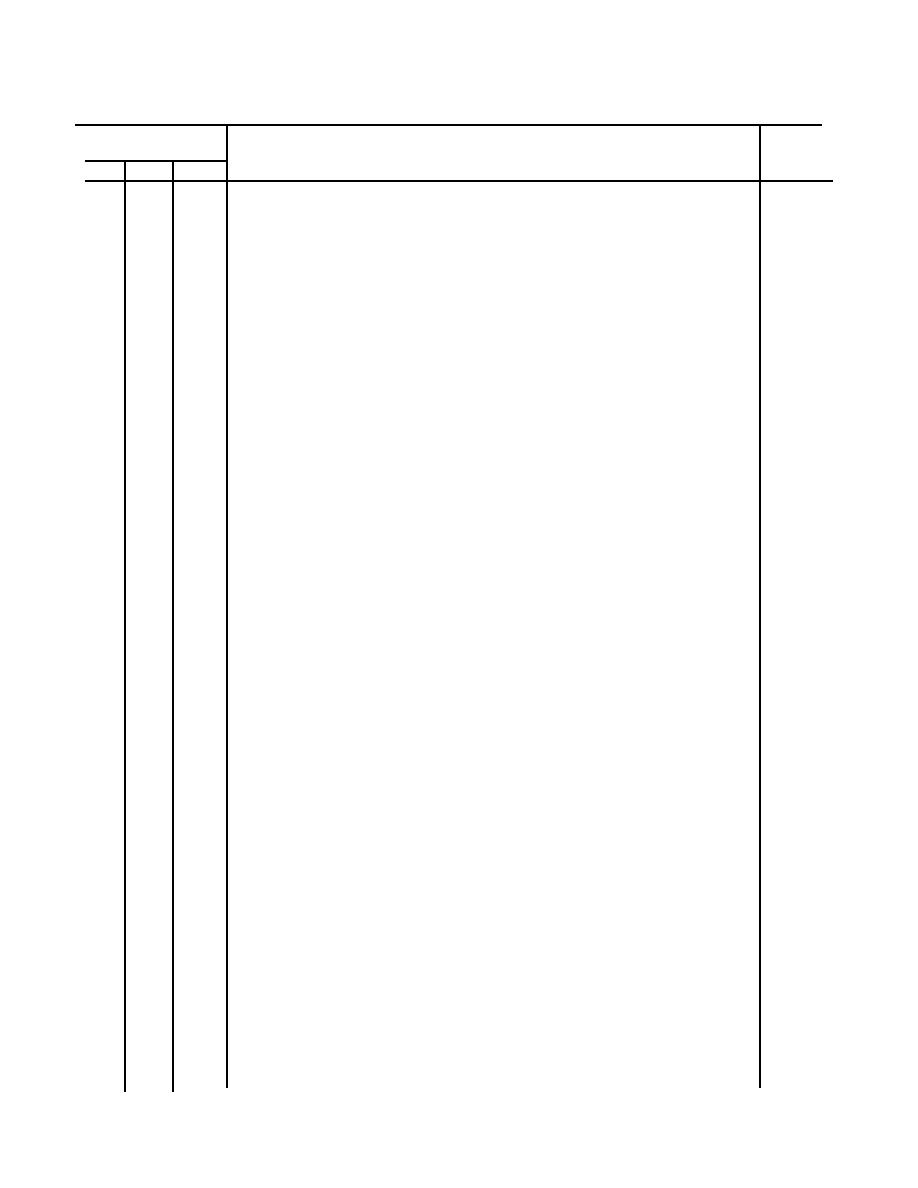

Table 3-1. Preventive Maintenance Checks and Services

B - Before Operation

D - During Operation

A - After Operation

INTERVAL AND

WORK

SEQUENCE NO.

ITEM TO BE INSPECTED

TIME

B

D

A

PROCEDURE

(M/H)

1

VISUAL INSPECTION

0.2

Inspect the compressed air and oil lines for loose connections or leakage.

Tighten loose air connections. Inspect for loose bolts and nuts to tighten as

necessary. Inspect to see that no object obstructs moving parts to prevent

damage.

2

0.1

Check oil level in the oil sump using a dip stick. Add oil as necessary. Check

lubricant reserve and replenish as required. Lubricate angle drive every 300

hours.

3

FUEL

0.1

Check level of gasoline in fuel tank. Fill tank as required.

4

INTERCOOLERS, AFTERCOOLER AND FAN

0.1

Inspect cooling tubes for distortion, dents and loose connections. Check the fan

for dents, bends, looseness or other defects. Correct all defects that impair

operation.

5

Monitor the air compressor continuously during operation. Observe any loose

0.2

fittings or developed leakage. Check for leakage at the control oil tube (nylon)

connectors. Report all defects beyond the scope of operator's maintenance for

subsequent maintenance action, identifying type and location of defect or

deficiency.

6

UNUSUAL NOISES

0.2

In particular, any development of noise from normal operation must be singled

out for investigation. If the noise is severe, or if the defect is detected and

considered detrimental to the unit, stop operation immediately and correct the

cause.

7

UNUSUAL OPERATION

0.1

Detect any vibration, over-heating smoking or any other cause that would

indicate a deviation from acceptable normal operation. Locate and correct the

cause. If the cause of unusual operation cannot be corrected, shut down the

compressor for subsequent maintenance action.

8

VISUAL INSPECTIONS

0.1

Inspect the air compressor for any obvious signs of damage, looseness of wear.

Tighten all loose nuts or bolts. Check for leakage at the control oil tube (nylon)

connectors.

9

PROTECTION

0.1

Store the compressor in a sheltered or enclosed area. Secure the air

compressor in position using the supplied frame assembly tie-down rings as

required.

3-4