TM 5-4310-343-35

(b) Replacement of first or second stage rings requires one hour minimum run at 2500 rpm and 1900 to 2100

psi delivery pressure or until blow-by is .3 cfm or less.

(c) Replacement of third or fourth stage cylinder and plunger assemblies requires a 12-hour run-in accordance

with the following schedule:

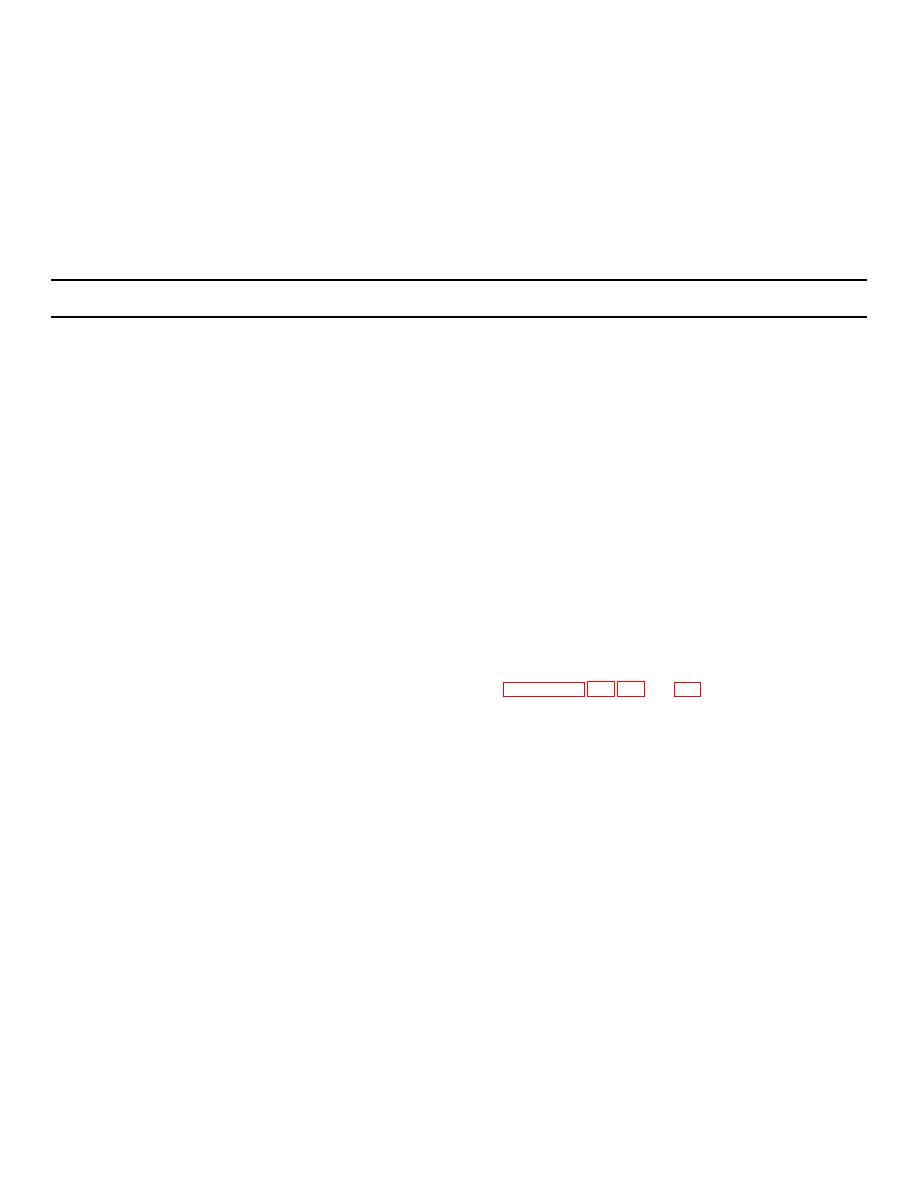

12 Hour Break-In Run

Delivery

Start (Hours)

Speed (RPM)

Pressure (psig)

Change (Hours)

0

1750

400-600

6:00

6:00

2500

1900-2100

10:00

10:00

3500 100

3100-3200

12:00

(d) Replacement of any other compressor part requires a one-hour minimum run and a visual check.

(5) Interstage pressure test.

CAUTION: Fill sump to capacity with lubricating oil MI-L-6085A. Adjust shaft speed

of compressor to 3750 RPM.

Adjust delivery pressure from the compressor to

3000 spi. Run the compressor for one hour. The following interstage pressures

should not be exceeded: 1st stage, 105 psi; 2nd stage, 460 psi; 3rd stage, 1,100

psi. If the pressure at any stage exceeds these limits, the compressor should be

checked for head clearance and valve travel per figures 5-3, 5-4, 5-5 and 5-6.

(6) Blow-by test. Connect a 0 to 0.5 cfm flowmeter to the blow-by port on the crankcase. With the compressor

unit operating at 3000 psi, check that indicated blow-by is not greater than 0.30 cfm.

(7) Oil consumption run. Oil pressure shall be measured as 80 to 120 psig during this test

(a) Fill oil sump with 200 cc of filtered oil (specification FSN 9150-753-4667).

(b) Pump up pressure to 3000 psi in back-up pressure-regulating system of universal compressor test

stand, part No. 890370 or equivalent.

5-51