TM 5-4310-372-14

Table 3-1. Troubleshooting - continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. EXCESSIVE COMPRESSOR OIL CONSUMPTION - continued.

Step 1. Check for incorrect or inferior grade of compressor oil – continued

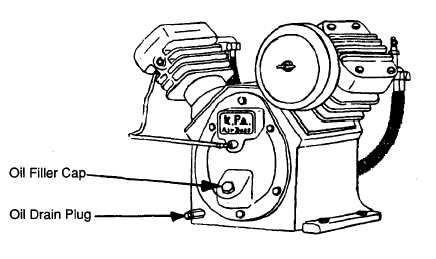

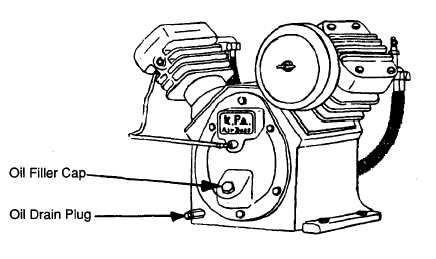

b. Position suitable container beneath compressor crankcase drain pipe and remove oil drain plug

from pipe.

c. Install drain plug when oil is completely drained.

d. Fill crankcase with 1.85 quarts (1 .75 liters) of the correct type of oil as follows:

Expected Temperature

Oil Type

Above 32°F(0°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OE/HD0 30

+40°F (4.5°C) to –10°F (-23°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. OE/HDO 1O

0°F(-18°C) to-25° F(–31.7°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OES

e. Install oil filler cap.

Step 2. Inspect for signs of leaks from oil drain plug or pipe.

Tighten oil drain plug.

3-8