TM 5-4310-452-14

2-14. DURING OPERATION.

a.

Perform all During (D) PMCS. Become familiar with the normal operation of the compressor unit and with the

readings on the indicators, Damage to the equipment, expensive repairs, and downtime can be avoided by an alert

operator who can detect a problem in its early stages and help organizational maintenance correct it before it becomes a

more serious problem.

CAUTION

Care must be taken to prevent air in

fuel system. Never allow fuel tank to

run dry. Air in fuel system will cause

engine power loss, rough running, or

engine to stall and not restart. If

engine stalls and will not restart,

notify

your

supervisor

to

have

organizational

maintenance

bleed

fuel system.

b.

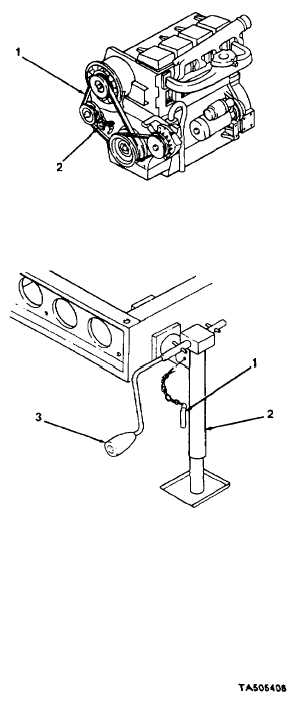

The compressor unit is equipped with a belt

break switch (2) that will stop the engine if an engine V-

belt (1) breaks. If the engine stops, check the engine V-

belts. If a V-belt is broken, notify your supervisor.

2-15. COUPLING UNIT TO TOWING VEHICLE.

WARNING

The 5-Ton Series trucks are the only

vehicles

authorized

to

tow

the

compressor

unit.

Unauthorized

vehicles

may

shear

drawbar

mounting bolts, allowing unit to

disengage

from

towing

vehicle

resulting in injury or death to

personnel.

NOTE

Before compressor unit is towed,

ensure that Before (B) PMCS have

been performed.

a.

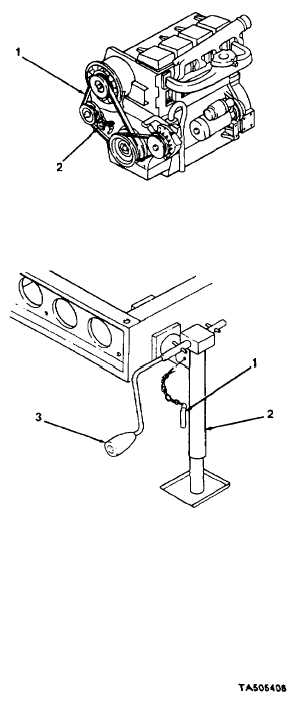

Raise

both

rear

leveling

jacks

(2)

with

handcrank (3). Remove locking pins (1) and place rear

leveling jacks in travel position. Insert locking pins to

lock rear leveling jacks in position.

2-20