ment must be carefully protected from sand, dirt, rain, sleet, and so on, and must be kept as clean as possible. Never lay

lubricating guns, couplers, or other equipment on the ground. When dispensing lubricant, wipe all dirt, moisture, or dust

from around the opening before unscrewing or removing the plug or cap.

b. Points of Application. Follow the detailed lubrication instructions given beneath each lubrication point illustration

(fig. 16) indicating procedures to be followed at each point. Apply the lubricant indicated on the lubrication order (fig. 16).

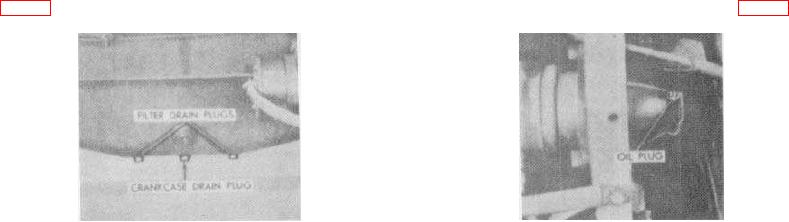

REFERENCE 8: Add B to 10 drops of oil to

REFERENCE 7: Drain oil filters before

starter end bearings.

removal. Drain crankcase.

Figure 16-Continued.

c. Cleaning. When dispensing lubricant, wipe all dirt, moisture, or dust from around the opening before unscrewing

or removing the plug or cap. Use a clean, lint-free cloth dampened with cleaning solvent.

d. Operation Immediately After Lubrication. After lubricating the compressor, and especially after filling the engine

crankcase, start and run the engine for approximately 5 minutes. The complete oil capacity for the crankcase includes the

5 gallon capacity of the sump and one-half gallon capacity of the sump and one-half gallon capacity of the oil filters.

During the five minute running interval, enough oil will be by-passed into the filters for correct operation. It will then be

necessary to check the oil level gage and refill the crankcase to the full mark.

e. Oil Filler and Breather Cap. Remove the oil filter and breather cap to fill the crankcase. Rinse the cap in gasoline

and dip it in lubricating oil before installing it on the valve cover.

f. Oil Level Gage. Pull out the oil level gage and wipe the end with a clean cloth. Insert the gage into the crankcase,

pull it

36