TM 5-4310-368-14

Section III. OPERATION UNDER USUAL CONDITIONS

2-3. ASSEMBLY AND PREPARATION FOR USE

No unpackaging is required. The only necessary installation is the air service hose (coiled on the inside of the

instrument panel access door) which is fitted to the hose disconnect fitting beside the instrument panel. See

depreservation instructions delivered with each unit.

2-4. INITIAL ADJUSTMENTS AND DAILY CHECKS

a.

Perform the B (before operation) checks and services from Table 2-2.

b.

Open all doors if operating in weather above freezing (32 ). These include instrument panel access door,

F

engine access door, dehydrator access door, front cooling air exhaust door, rear cooling air exhaust door, and

sliding side cooling door. Between 32 and 0 , close the front and rear cooling air exhaust doors. Below

F

F

0 to -50 , close all doors except the instrument panel access door.

F

F

c.

Push the clutch operating lever in to disengage the clutch.

d.

Pull the magneto ground switch down (Fig. 2-2).

e.

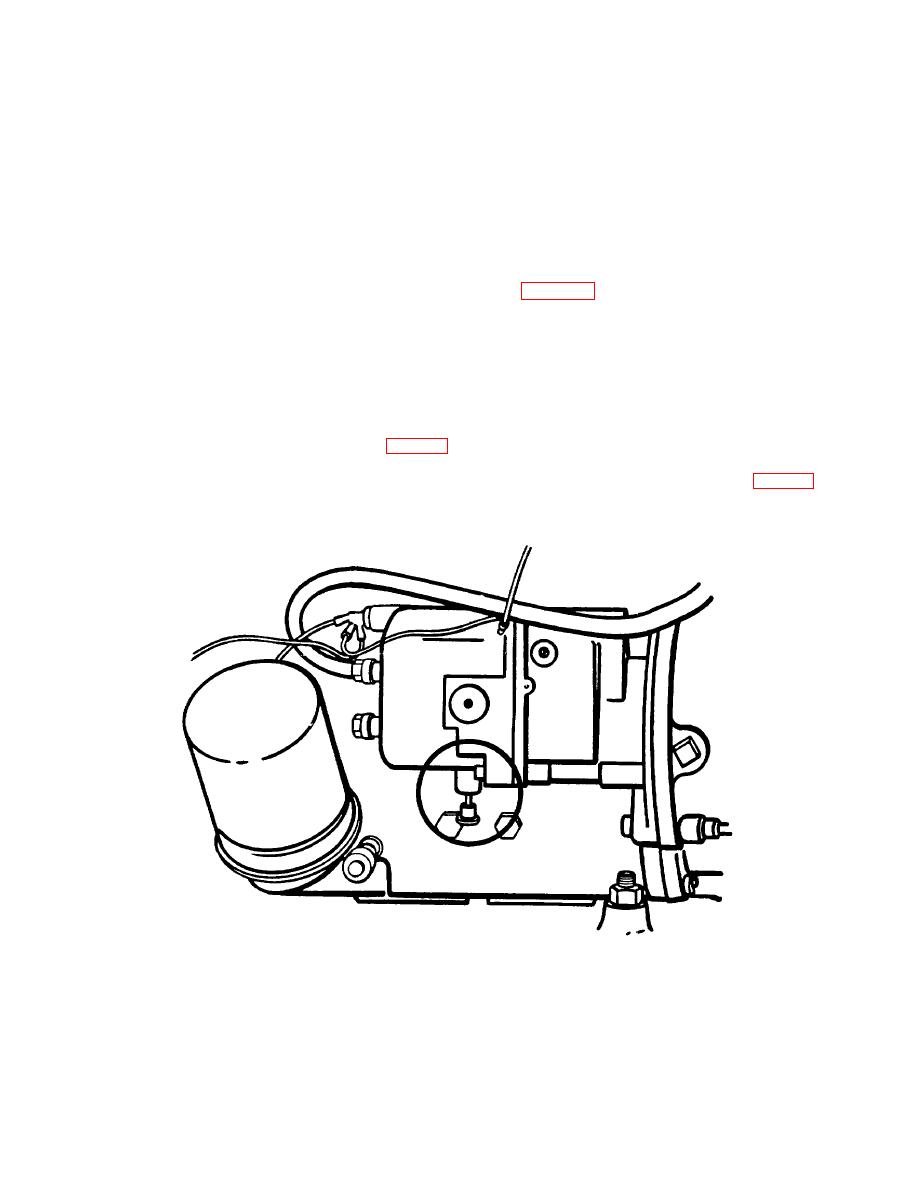

Pull out spring tab and bend it so that the end fits in the slot in the engine oil pressure switch (Fig. 2-3).

Figure 2-2. Magneto Ground Switch

2-10