TM 5-4310-371-14

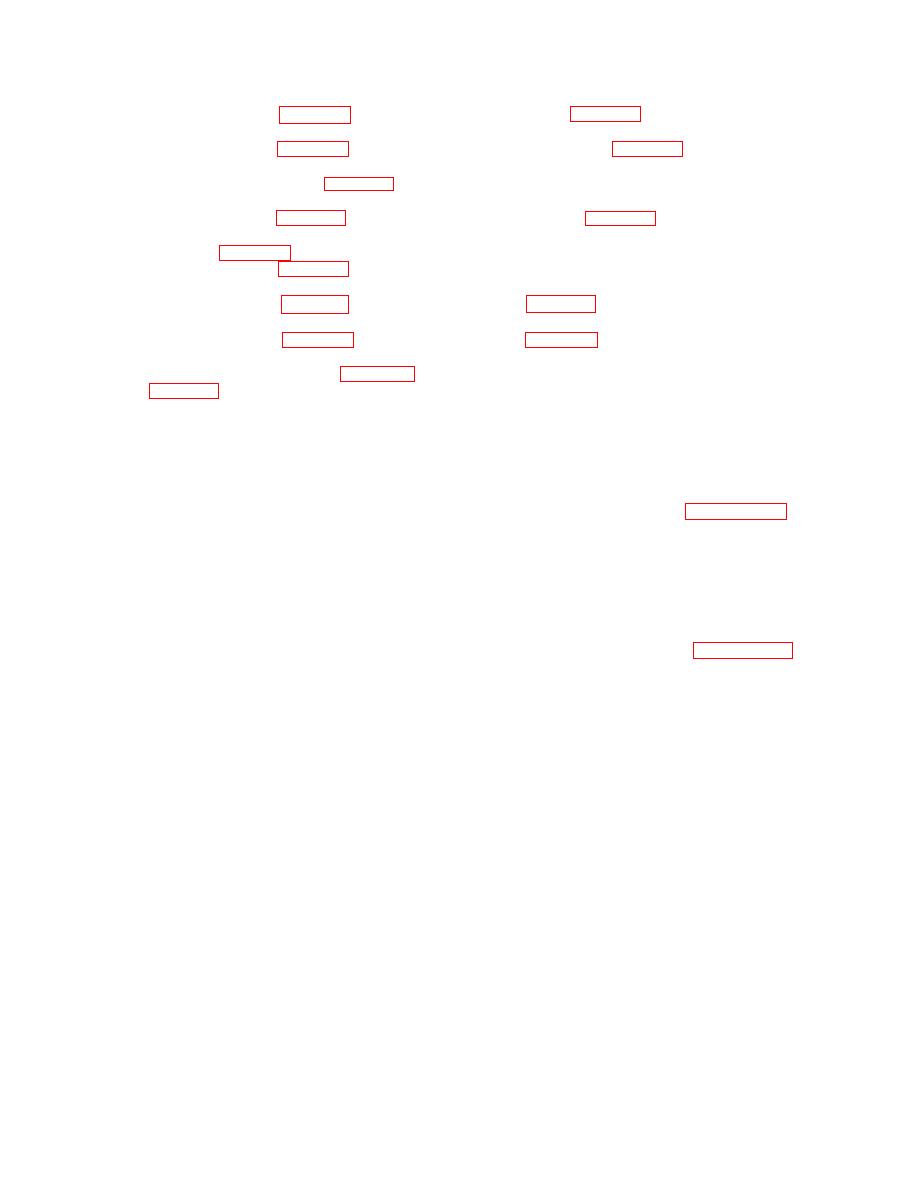

(4) Press front bearing (figure 5-1, item 10) back into front housing (figure 5-1, item 3).

(5) Install bell housing (figure 5-1, item 9) back onto rotor assembly shaft (figure 5-1, item 12).

(6) Install bell housing slinger (figure 5-1, item 8) onto rear of shaft so that it is flush with bell housing.

(7) Install sleeve bolts (figure 5-1, item 7) back into position on stator (figure 5-1, item 13).

(8) Install fan (figure 5-1, item 6) back onto shaft as far as it will go and in line with key, and then immediately

replace tension clip (figure 5-1, item 5) onto shaft.

(9) Install rear housing (figure 5-1, item 4) and front housing (figure 5-1, item 3).

(10) Install housing nuts (figure 5-1, item 2) onto sleeve bolts (figure 5-1, item 7) and tighten down securely.

(11) Install front housing slinger (figure 5-1, item 1) onto shaft so that it is flush with outside of front housing

d. Rotor Assembly Inspectio n and Replacement

(1) Inspection check to see if rotor rings (windings) are spotted, rough, eccentric, or broken. If any of these

conditions exist, the rotor assembly must be replaced.

(2) Replacement replace rotor assembly in accordance with procedures described in paragraph 5-1a.

e. Stator Assembly Inspection and Replacement

(1) Inspection check to see if stator assembly windings are dried out and/ or cracked and if stator assembly

cables are loose, frayed, split or disconnected. If any of these conditions exist, the stator assembly should

be removed and sent to the next level of maintenance to be repaired.

(2) Replacement replace stator assembly in accordance with procedures described in paragraph 5-2a.

f. Starter Switch Replacement

(1) If starter switch malfunctions, check all terminals to see that starter switch has been wired properly

(figure 2-2) and that connections are tight. Loose connections will cause starter switch to work improperly

or not at all.

(2) Starter switch wiring procedures (figure 2-2).

5-12