TM 5-4310-373-14

This task covers:

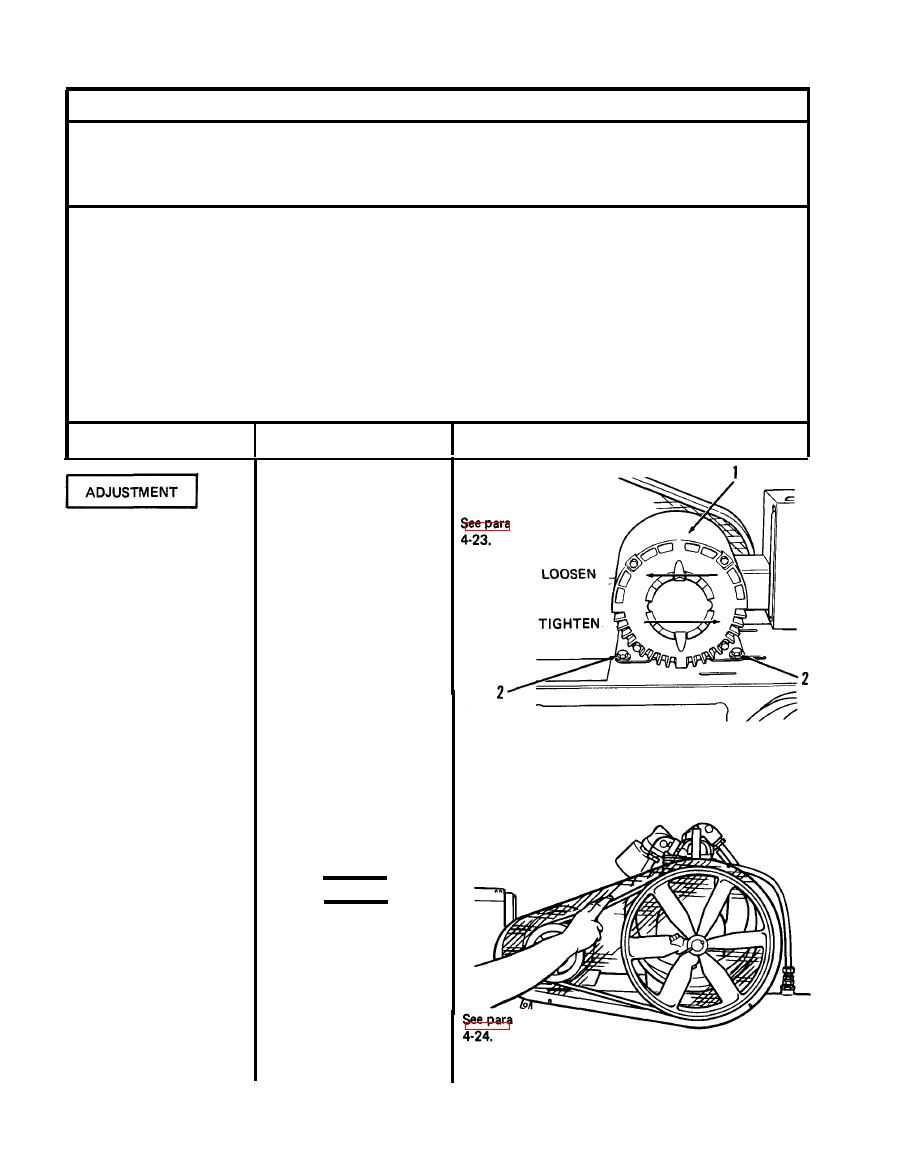

The adjustment of the V-belt tension.

INITIAL SETUP

Equipment Condition:

Tools:

Compressor Unit OFF

Main power OFF

Materials/Parts:

None

Approximate Time Required (minutes):

Personnel Required:

10

1 Mechanic

REMARKS

ACTION

LOCATION/lTEM

Remove.

1. Belt guard cover

Loosen 4 bolts.

2. Electric motor mounting

bolts (2)

Figure 4-46. Motor mounting tighten

Belt tension is right when belts move 1/2 inch when

Electric motor (1)

Slide in direction of arrows

3.

pushed on half way between pulley and flywheel.

and adjust position for

proper belt tension.

Tighten when proper belt

4.

Electric motor mounting

tension is achieved.

bolts (2)

CAUTION

Too little belt tension causes

belts to overheat and wear out

prematurely. Too much ten-

sion causes bearing wear in

motor and compressor.

5.

Install.

Belt guard cover

Figure 4-47. V-belt tension

4-38