(3)

If gap is incorrect, slightly loosen two

c.

Installation.

screws (8), insert screw driver in

(1)

Position the magneto (6) on the unit.

adjusting slot (5) and open or close

(2)

Install one cap screw (2, fig. 22) on

points until proper gap is attained.

the pump side of the magneto (9, fig.

(4)

Tighten the two screws (8), and

recheck the point gap.

(3)

Install one cap screw (4, fig. 21) on

(5)

Install the rotor cap on the cam.

the reel side of the magneto.

(6)

Install the magneto end cap on the

d.

Adjustment.

magneto housing and secure by

(1)

Rotate cam until points (7) are at

installing four screws (8, fig. 20), and

maximum opening. Check gap with

tooth-type lockwashers.

feeler gage.

(7)

Connect the magneto ground cable

(2)

The points should have an opening of

(17) to the magneto cover.

0.015 inch.

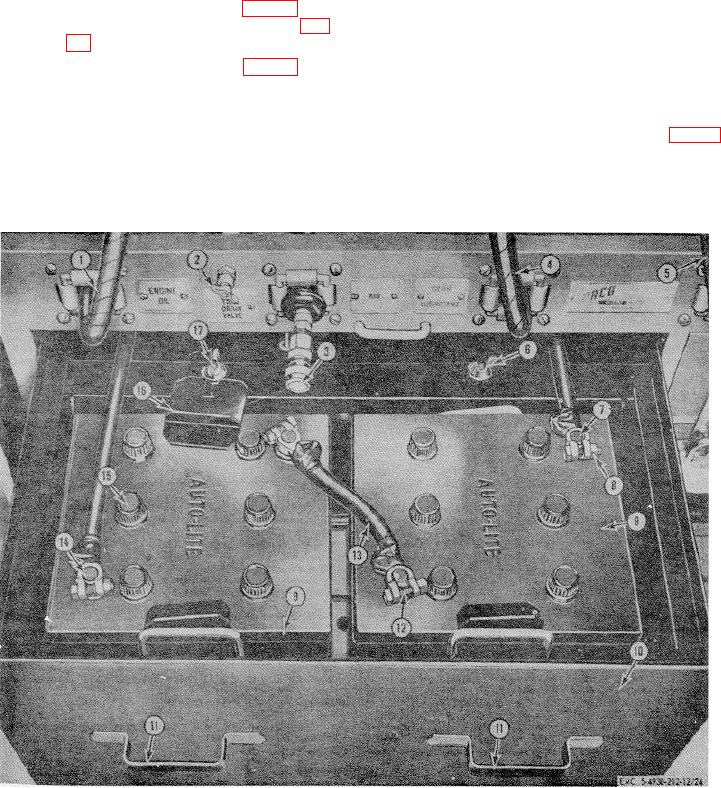

1

Engine oil dispensing line

7

Negative terminal

13

Jumper cable

2

Air tank drain valve

8

Nut, 5/16-18 (4 rqr)

14

Positive terminal

3

Air line coupler

9

Battery

15

Battery filler cap (12 rqr)

4

Gear lubricant dispensing line

10

Battery box

16

Tie-down clamp (4 rqr)

5

Grease GAA dispensing line

11

Battery box handle

17

Tie-down bolt (2 rqr)

6

Wing nut 3/8-16 (2 rqr)

12

Bolt, 5/16-18 x 1 in. Ig (4 rqr)

Figure 24. Servicing batteries.

58