TM 9-4310-397-14

(t)

Check piston pin and piston bore specifications. If either are not within specification replace pin and

piston.

Pin/Bore Specifications

Piston Pin OD

Small pin .............................................. .1.374 - 1.375 in. (34.92 - 34.93 mm)

Large pin .............................................. 1.6247 - 1.6253 in. (41.27 - 41.28 mm)

Wear Tolerance. ................................... 0.005 in. (0.13 mm)

Piston Bore (For Pin)

Small pin .............................................. 1.3753 - 1.3757 in. (34.93 - 34.94 mm)

Large Pin . ............................................ .1.6254 - 1.6258 in. (41.285 - 41.295 mm)

NOTE

Some piston bores are elliptical, the width being 0.0015 in. (0.038 mm)

larger than the above specifications.

(2)

Liners.

(a)

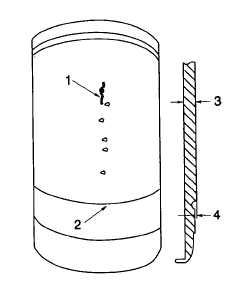

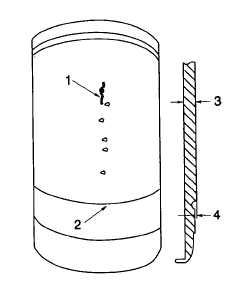

Inspect exterior length of liner for pitting (Figure 6-80, 1). Check packing step for erosion (2). If

pitting or erosion is observed, measure the depth of pits and erosion with a fine wire or needle. If

pitting has occurred, check condition of coolant.

Figure 6-80. Inspect Liner for Pitting

(b)

Replace liner if any of the following problems are noted:

1

Depth of any pit is one-half or more of liner thickness (3).

2

Depth of erosion is one-half or more of the packing step (4).

6-65