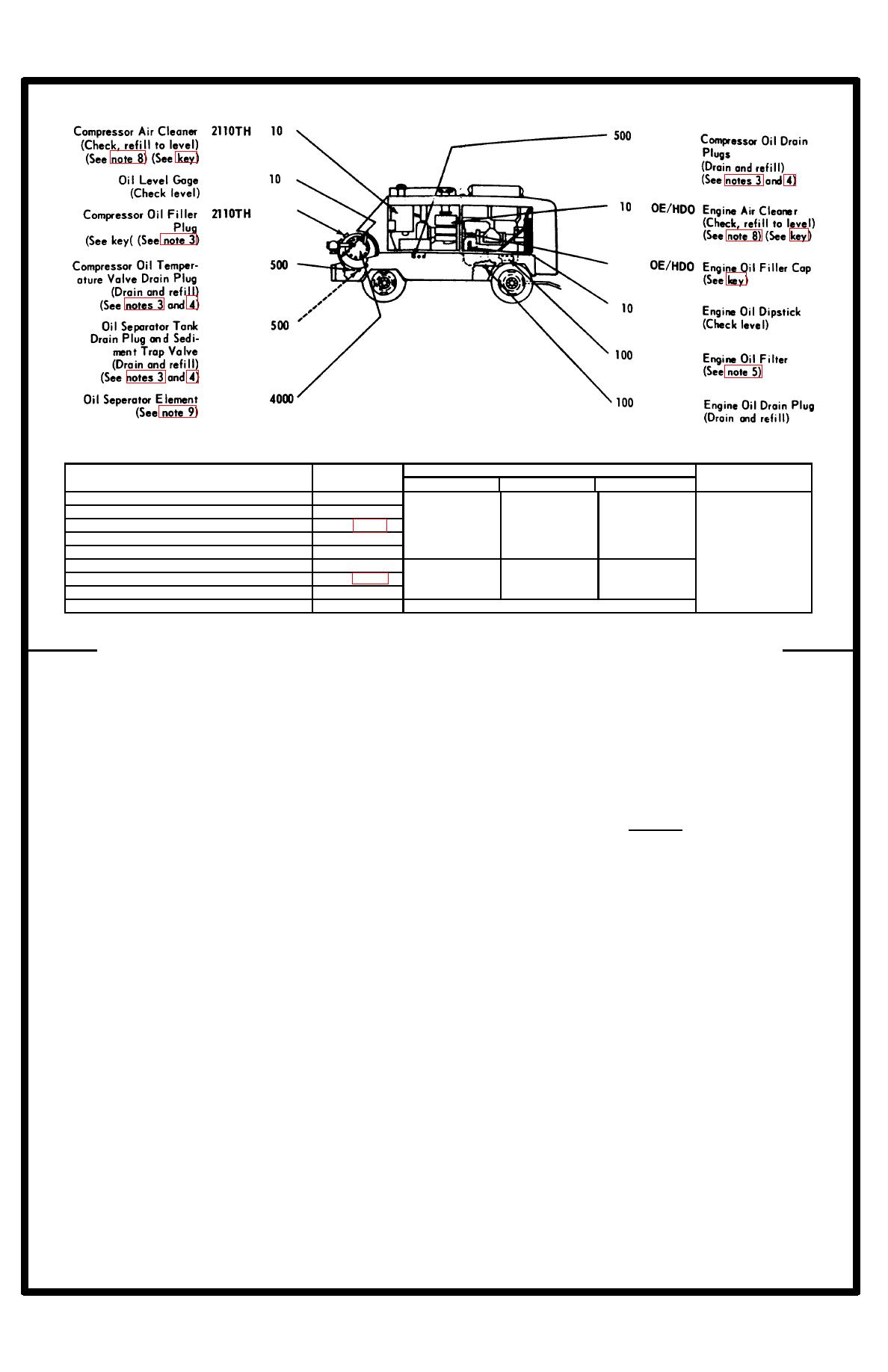

LO 5-4310-219-12

LUBRICANT INTERVAL

INTERVAL LUBRICANT

key

notes 3 and 4

note 8

note 3

- KEY -

EXPECTED TEMPERATURES

INTERVALS

LUBRICANTS

CAPACITY

Above +32 F

+40 F to -10 F

0 F to -65 F

OE/HDO-LUBRICATING OIL, Engine

Engine Crankcase

29qt

Engine Air Cleaner

See Note 8

OE/HDO 30

OE/HDO 10

OES

Intervals

Oil Can Points

given are

OES-LUBRICATING OIL, General Purpose

in hours of

2110TH-LUBRICATING OIL, General Purpose

normal

Compressor Air Cleaner

See Note 8

2110TH

2110TH

OES

operation

Compressor Oil System

120 qt

GAA-GREASE, Automotive and Artillery

ALL TEMPERATURES

FOLD

FOLD

NOTES:

8. ENGINE AND COMPRE SSOR AIR CLEANER.

Every 50 hours

1. FOR OPERATION OF EQUIPMENT IN PROTRACTED COLD

disassemble, clean, reassemble, and fill to oil level. Serial No. Ranges and

Capacities: 600AR 18589 thru 600AR 18838, 5 1/2 qt. ea; 600AR 21871

TEMPERATURES BELOW - 10 F. Remove lubricants prescribed in the key

thru 600AR 22070, 5 qt. ea; 600AR 23671 thru 600AR 23880 and 600AR

for temperatures above - 10 F. Clean parts with SOLVENT, dry-cleaning.

23882 thru 600AR 23933, 7 qt. ea.

Relubricate with lubricants specified in the key for temperatures below - 10

F.

9. OIL SEPARATOR ELEMENT: The oil separator element shall be

replaced every 4,000 hours of operations. This procedure is necessary due

2. OIL CAN POINTS. Every 50 hours lubricate regulator and governor

to the depositing of metal salts on the element as the oil is separated from

linkage, control linkage, pins and clevises, and all exposed adjusting threads

the air. Do not attempt to clean the element or re-use the element because

with OE/HDO.

of its clean appearance.

3. CAUTION: Release air pressure before removing drain plugs or fill

WARNING

plug. Do not use inflammable diluents in compressor oil system.

Destroy used element to prevent accidental re-use.

4. COMPRESSOR OIL SYSTEM - SERIAL NO. RANGES FROM 600AR

Over pollution of metal salts collecting on the element

18589 THRU 600AR 23880. Every 500 hours to drain oil, remove plugs from

can become a hazardous condition by lowering the flash

oil temperature valve, oil separator tank, compressor, compressor cooler, oil

point and causing a fire in the separator.

vent, and compressor oil filter. Every 10 hours, to drain water and sediment,

remove plug from oil temperature valve and drain only until oil appears.

10. LUBRICANTS. The following is a list of lubricants with the Military

SERIAL NO. RANGE 600AR 23882 THRU 600AR 23933. To drain, follow

Symbols and applicable specification numbers.

above procedure and also open water sediment trap valve. Every 10 hours,

OE/HDO MIL-L-2104C

OES MIL-L-10295

to drain water and sediment, open sediment trap valve and drain only until oil

GAA MIL-G-10924

2110TH MIL-L-17672

appears.

Copy of this Lubrication Order will remain with the equipment at all times;

5. ENGINE OIL FILTER. Every 100 hours remove filter element, clean

instructions contained herein are mandatory.

housing, install new element, fill crankcase, operate engine for five minutes,

and check for leaks. Allow 15 minutes for oil to settle, check level, and bring

to full mark.

BY ORDER OF THE SECRETARY OF THE ARMY:

6. COMPRESSOR OIL FILTER. Every 10 hours turn handle one turn

CREIGHTON W. ABRAMS

preferably after stopping unit. Every 100 hours remove filter element from

General, United States Army

filter base, wash in approved solvent, and re-install element. If lacquer

OFFICIAL:

Chief of Staff

deposit is noted, change compressor oil completely to avoid vane sticking in

the compressor.

7. WHEEL BEARINGS. Every 1000 hours remove wheels; clean and

VERNE L. BOWERS

inspect all parts, replace damaged or worn parts, repack bearings, and

Major General, United States Army

reassemble.

The Adjutant General

DISTRIBUTION: To be distributed in accordance with DA Form 12-25A (qty

rqr block no. 41). Operator requirements for Air Compressor, 600 CFM.

PGPO: 1998-432-760 (60442)

P U.S. GOVERNMENT PRINTING OFFICE: 198 O-432-760 (60442)