LUBRICATION

ORDER

28 MARCH 1968

COMPRESSOR, RECIPROCATING, AIR, RECEIVER MOUNTED,

ELECTRIC MOTOR DRIVEN,5 CFM, 17S PSI, (CHAMPION

PNEUMATIC MODEL .0 CAW20HM-1 AND MODEL

60 CAW20HM-2)

Reference: C9100-IL

Drain crankcase when hot. Fill and check level.

Intervals are based on normal hours of operation.

Adjust to

compensate for abnormal operations and severe conditions. During

inactive periods sufficient lubrication must be performed for adequate

preservation.

Clean parts with SOLVENT, dry-cleaning, or with OIL, fuel, Diesel. Dry

before lubricating.

Relubricate after washing.

- KEY -

EXPECTED TEMPERATURES

Above +32

+40 to -10

0 to 65

LUBRICANTS

CAPACITY

INTERVALS

F

F

F

F

OE -OIL, Engine, Heavy Duty

Intervals

Compressor Crankcases

1/2 qt ea

OE 30

OE 10

OES

given are in

hours of norm-

OES -OIL, Engine, Sub-zero *

al operation

FOLD

FOLD

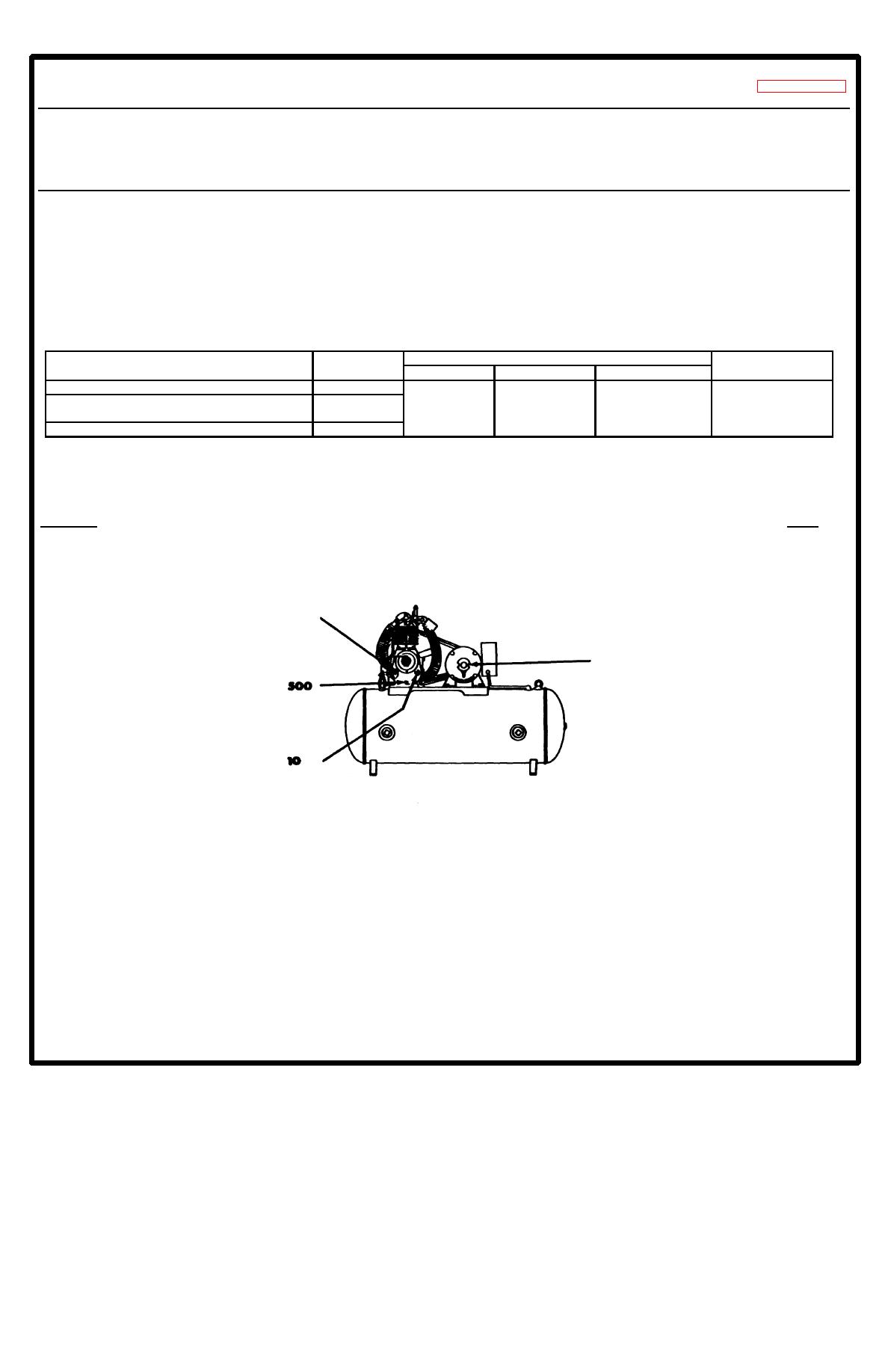

LUBRICANT * INTERVAL

INTERVAL LUBRICANT

Compressor Crankcase OE

Fill Plug

Motor Borings

(Sealed borings no

lubrication required)

Compressor Crankcase

Drain Plug

(Drain and Refill)

Compressor Crankcase

Oil Level Sight Gage

(Check Level)

NOTES:

Copy of this Lubrication Order will remain with the equipment at all

times; instructions contained herein are mandatory.

1.

FOR OPERATION OF EQUIPMENT IN PROTRACTED COLD

TEMPERATURES BELOW-10 . Remove lubricants prescribed in the

F

BY ORDER OF THE SECRETARY OF THE ARMY:

key for temperatures above-10 . Relubricate with lubricants specified

F

in the key for temperatures below-10 .

HAROLD K. JOHNSON,

F

General United States Army,

OFFICIAL:

Chief of Staff.

2. LUBRICANTS. The following is a list of lubricants with the Military

Symbols and applicable Specification numbers.

KENNETH G. WICKHAM,

OE-MIL-L2104

Major General United States Army,

OES-MIL-L-10295

The Adjutant General.

DISTRIBUTION:

To be distributed in accordance with DA Form 12-25, Section I, Organizational Maintenance Requirements for Air Compressors (Reciprocating) 5 CFM.

* U.S. GOVERNMENT OFFICE: I9970-4123 (4042)