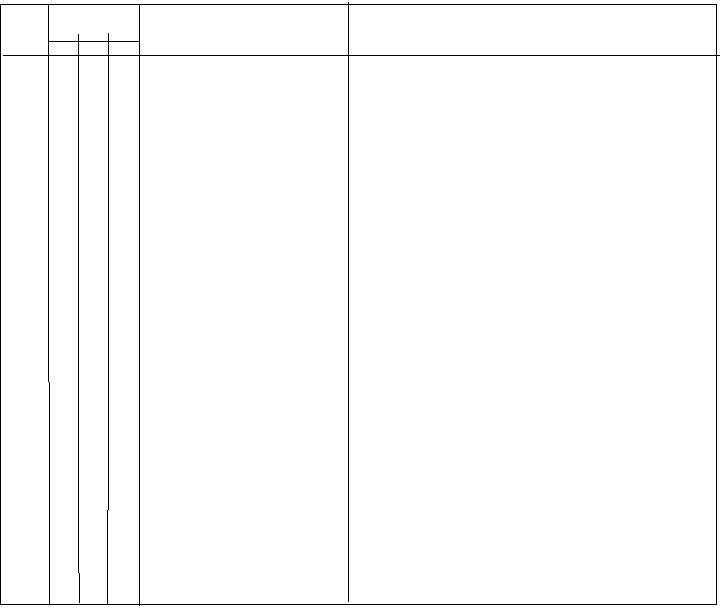

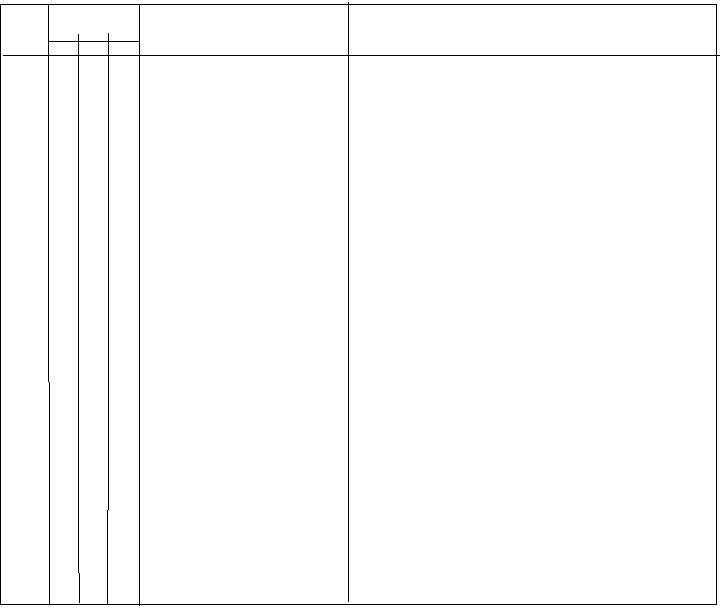

TM 5-4220-227-14

Table 4-1. Unit Preventive Maintenance Checks and Services (PMCS) (Cont).

W - Weekly

M- Monthly

Y - Yearly

Interval

Item

Item to be Inspected.

Procedures

No.

W

M

Y

15

*

High Pressure Hoses

Inspect for cuts, nicks and cracks and replace if

damaged.

16

*

Heater/Chiller Unit

Inspect fins for cracks, dirt and grease. If unit is

inoperative, refer to para. 5-13.

17

*

Scrubber Assembly

Inspect canister for clogged holes and damage.

If canister is inoperative, refer to para. 5-13.

18

*

View Port Assembly

Inspect retaining bolts for proper torque. Refer to

Appendix F, torque limits.

19

*

Shell Penetrates

Inspect retaining bolts for proper torque. Refer to

Appendix F, torque limits.

20

*

Gages

Check for calibration dates on pressure relief valve

and all pressure gages on chamber inside and out.

Refer to para. 6-6.

21

*

Cots

Inspect for attachment of cotter pin and chain.

Inspect for attachment of grounding strip. Refer to

paragraph 4-26.

22

*

GFI

Press TEST button to test. Circuit breaker should

trip. Reset to up position (ON).

23

*

Medical Lock Assembly

Check for proper operation of door and locking

pin assembly.

24

*

Skid

Check for corrosion and loose bolts.

25

*

Air System (Hoses, Gages,

Check for leaks. Apply soapy solution to all

Penetrators, Pipe Fittings,

connections and fittings and check for bubbles at

Valves)

full operating pressure.

4-10