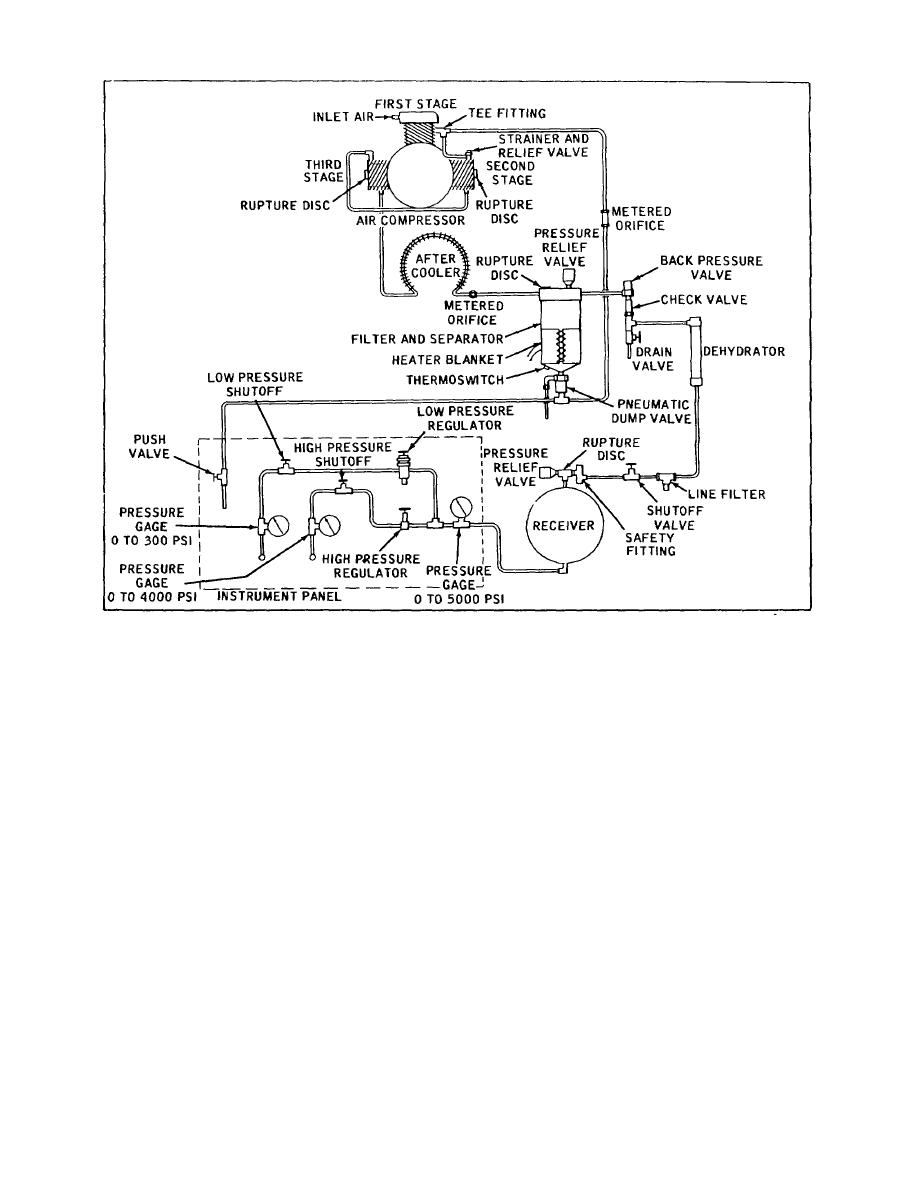

Figure 1-5. Pneumatic System Schematic Diagram (Model 3800219-1)

valve reseals (closes), preventing the further escape of

outlet port of the filter and separator assembly, consists

air, when the pressure drops to about 3200 psig.

basically of an aluminum alloy valve body provided with

an inlet fitting, an outlet fitting and an adjustable valve

1.5.7.2 The pressure relief valve assembly consists of a

cap. A drilled passage connecting the inlet and outlet

cylindrically shaped, aluminum valve body which

fittings contains a piston seat and a spring-loaded

contains a spring-loaded piston, a ball-type valve, a

piston. The setting of the valve cap determines the

stem and an adjusting screw. Under normal pressure

force which the spring exerts to maintain the piston

conditions, the ball is seated against a nylon washer, or

seated against the piston seat (i.e., valve closed).

seat, installed in the bore of the piston, and no air

escapes through the assembly. However, when air

1.5.8.2 The piston of the back pressure valve is held

pressure in the system increases above a

against the piston seat, preventing the flow of air from

predetermined value, the spring-loaded piston and the

the filter and separator assembly, until the pressure in

ball are displaced until the ball rests against the end of

the separator shell reaches a predetermined value.

the stem which extends into the piston bore. A further

When air pressure at the inlet of the back pressure

increase in pressure causes additional displacement of

valve is between 2450 and 2650 psig, depending on the

the piston, unseating the ball and allowing air to escape

back pressure at the outlet fitting, the piston is forced

to atmosphere through the bore of the piston and holes

away from the piston seat, compressing the spring.

drilled in the adjusting screw. When air pressure in the

Opening of the drilled passage through the piston seat

system is reduced to an appropriate level, the spring

allows high-pressure air to flow from the filter and

force moves the piston toward the ball, closing the valve

separator assembly through the back pressure valve.

passage and preventing the further escape of air.

When air pressure in the filter and separator assembly

drops to approximately 2000 psig, the spring forces the

piston back against the piston seat, effectively closing

1.5.8 BACK PRESSURE VALVE

the back pressure valve and preventing the further flow

of air.

1.5.8.1 The back pressure valve, mounted or. the

11