SECTION II

OPERATING INSTRUCTIONS

2.1 TOWING AND POSITIONING

2.2.3

Inspect the fuel filter (see Figure 1-4); if

necessary, empty and clean the sediment bowl. Check

2.1.1 The tow bar attached to the front of the cart

the engine assembly in accordance with the instructions

enables the compressor package assembly to be

contained in Part II: of this manual.

attached to the pintle of most standard tow trucks.

Make certain the tires are uniformly inflated to a

Always make sure the foot which supports the front ends

pressure of 20 to 25 psig and that the wheel brakes are

of the cart is retracted and the wheel brakes released

set.

before attempting to tow the unit. Do not exceed a

speed of 20 miles per hour when towing on pavement;

2.3 PRE-OPERATING SERVICING

reduce speed in accordance with the condition of the

terrain. Secure the tow bar in the vertical position when

it is not being used.

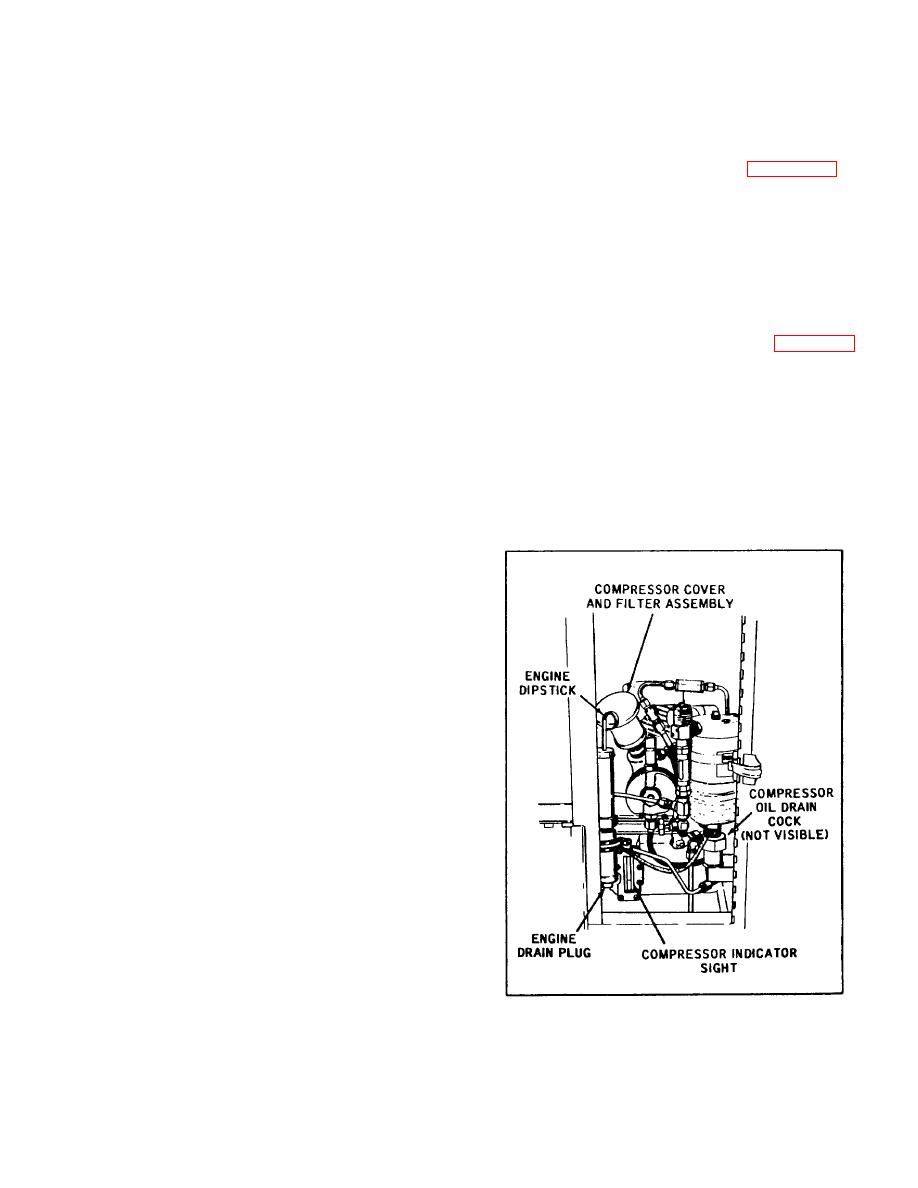

2.3.1 COMPRESSOR LUBRICATION (See Figure 3-1)

2.1.1 The cart handle attached to the tow bar allows the

2.3.1.1 Make sure the compressor package assembly is

compressor package assembly to be moved manually

as level as the terrain permits, then check the level of

for short distances and for proper positioning of the

the oil in the compressor reservoir by observing the

equipment. When the unit is located in its operating or

indicator sight mounted on the side of the reservoir. If

storage location, step on the foot pedal at the front of

necessary, remove the cover and filter assembly from

the cart to drop the support foot and set the wheel

the breather assembly installed in the compressor

brakes. Secure the cart handle in the vertical position.

crankcase, and add oil to bring the level up to the FULL

mark on the indicator sight. Approximately five pints of

oil are required to fill the reservoir. Be sure to replace

2.2 PRE-OPERATING INSPECTIONS

the cover and filter assembly.

NOTE

Refer to Instruction Decal on engine

compartment access door.

2.2.1 Open all access doors and perform a thorough

general inspection of the compressor package

assembly, looking for obvious indications of damage

such as oil or air leaks, loosely mounted or missing

parts, bent or broken fins on the interstage connecting

tubes and cylinders, damaged or improperly zeroed

pressure gages, and broken safety wires. Check all

pneumatic and fuel systems connections for tightness.

Make certain all surfaces of the unit are free of

obstructions and deposits that would impair the

operation of the engine, compressor and other

components, or prevent efficient cooling of the units.

Examine the air hose, the pressure servicing valve and

the chuck for damaged fittings, swelling, rupturing, and

other indications of deterioration. Inspect the fuel tank

for dents, cracks, leaks, and other damage.

2.2.2 Remove the attaching screws and lock washers

and lift the silencer cover and intake filter from the

compressor first stage cylinder head. If necessary,

clean the filter by washing in ethyl alcohol (Federal

Specification O-A-396) and allow the element to air dry.

Figure 2-1. Compressor and Engine

Use a clean cloth moistened with dry-cleaning solvent

Lubrication Points

(Federal Specification P-S-661) to clean the inside of

the silencer cover, then remove all residue by wiping

with a clean, lint-free cloth. Replace the intake filter and

silencer cover on the first stage cylinder head.

15